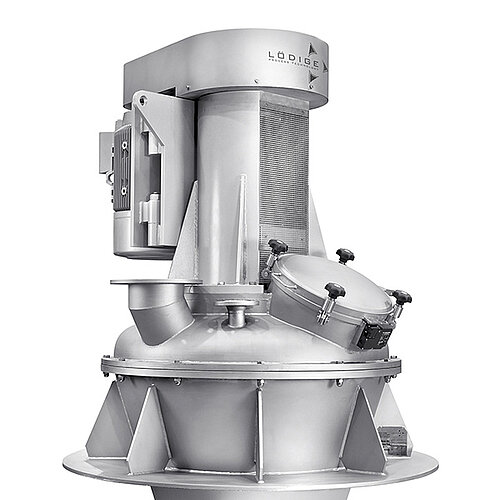

VERTICAL MIXING IN LÖDIGE MACHINES

LÖDIGE vertical mixers offer a space saving alternative to our well-established horizontal mixers. The vertical mixers are particularly advantageous because they are easily accessible, easy to clean and take up less space on site. Good mixing quality and short mixing times are self-evident.

They are mainly used in the cosmetics, food, pharmaceutical and plastics industries. They are ideal for applications such as the granulation of tablet formulations in the pharmaceutical industry or the production of face powder in the cosmetics industry. They are also ideal for mixing and processing medium to high viscosity compounds and various plastic mixes.

THE MIXING PROCESS IN A VERTICAL LÖDIGE MIXER

During the mixing process, the product is lifted and circulated by a mixing impeller rotating close to the bottom of the vertical drum, ensuring fast and efficient mixing. The addition of liquids and the use of choppers are also possible in our LÖDIGE machines. Furthermore, the mixing drum can be equipped with a temperature control jacket for heating or cooling the product.

LÖDIGE vertical mixers can process powders as well as granules or pasty products. Depending on the machine type, the machine drive is located above or below the mixing drum.

LÖDIGE VERTICAL MIXING SYSTEM

LÖDIGE machines are renowned for their ease of use and reliable, proven mixing concept. Discover all the LÖDIGE vertical mixers below:

Mixing granulator (Laboratory machine)

- Laboratory mixing granulator with exchangeable vessel

- Mixing, granulation and temperature control in one machine

- Exchangeable vessels with a volume of 1, 5, 10 or 15 l

- GMP-compliant design

- User-friendly, integrated control system

- Operation-ready system

THE LÖDIGE MIXING GRANULATOR

- Mixing granulator for pharmaceutical products, cosmetics and food

- GMP-compliant design

- Modular WIP system for the machine and all additional components

- Automatic liquid addition in different versions

- New pharmaceutical controls

- Temperature control jacket for heating/cooling

- Integrated sieve on machine outlet

- Vacuum feeder

- Customised ATEX concepts

The wet mixer

- High mixing quality even for critical products

- Application of high shearing forces

- Easy operation and cleaning

- Reliable and time-tested mixer concept

NO SUITABLE MACHINE FOUND?

WE ARE CERTIFIED & APPROVED

Our commitment to quality is officially confirmed by recognised testing bodies. Find out more here about our industry-specific approvals and certificates.

CONTACT US NOW

We work closely with our customers to develop the best solutions for each environment. With a team of experienced engineers and a focus on customer specific requirements, LÖDIGE offers support from concept to implementation. Find the right contact for your needs here: