PERFECT MIXING IN THE LÖDIGE HORIZONTAL MIXER

In almost all industries, mixing is an essential production step and critical to the quality and consistency of the end product. LÖDIGE horizontal mixers feature advanced technology that not only provides exceptionally fast and efficient mixing, but also ensures uniform consistency and homogeneity of the end product. Our mixers are optimised for the demands of modern industrial production and represent the state of the art in mixing technology.

MIXING AND PROCESSING IN A HORIZONTAL SYSTEM

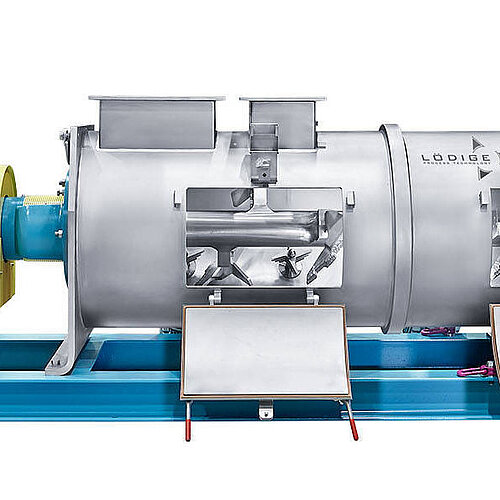

LÖDIGE mixers are suitable for a wide range of products - from powdery to granular components or sludges. Thanks to the special arrangement of the Ploughshare® Shovels, these machines achieve a three-dimensional movement of the mix.

The combination of size, number, positioning and peripheral speed of the mixing elements prevents the formation of dead space and enables precise mixing. In addition, LÖDIGE mixers are well-known for their ease of maintenance, long service life and adaptability to specific mixing requirements - including the option of integrating high speed choppers for improved mixing efficiency.

CONTINUOUS MIXING IN A HORIZONTAL SYSTEM

Our Ploughshare® Mixer for continuous operation works according to the fluid bed principle, mechanically generated and introduced to industrial mixing technology by LÖDIGE. The mixing elements are specifically adapted to each customer’s application. The throughput rates of this mixing system are high and vary depending on the residence time, filling level and product properties. In continuous operation, the process can be run at filling levels between 20% and 50% without affecting the mixing quality.

The mixing elements are designed to remix the product continuously during its residence time and before it is discharged for further processing. The adjustment of the discharge opening by means of a slide or adjustable weir has a significant effect on the residence time. Variations in the feed rate upstream can be easily compensated by this discharge system.

REVOLUTION THROUGH INNOVATION

Discover the LÖDIGE pioneering mixer technology which has revolutionised mixing and processing. Our patented innovation sets new standards in the efficiency and quality of the mixing process. Homogeneous mixes are achieved in the shortest possible mixing time.

BATCH MIXING IN A HORIZONTAL SYSTEM

The LÖDIGE Ploughshare® Mixer is ideal for batch mixing in a horizontal system - especially for batch processes where flexibility and precision are required. This system allows the mixing parameters to be precisely adjusted to the specific characteristics of each batch, ensuring optimum mixing.

The Ploughshare® Batch Mixer also operates according to the fluid bed principle and is designed to achieve rapid and thorough mixing in the shortest possible time. The defined arrangement of mixing elements avoids dead space, significantly improving the efficiency of the mixing process. In addition, easy access to all internal mixer parts not only facilitates cleaning and maintenance but is also essential in the production of high hygiene products.

THE LÖDIGE HORIZONTAL MIXER

Each machine is designed to maximise the efficiency of the mixing process while ensuring the highest standards of product quality and safety. All the LÖDIGE horizontal mixers can be found below:

Ploughshare® Mixer (Laboratory machine)

- Guaranteed LÖDIGE quality

- Attractive value for money

- Functional design

- Ideal for your product and process development

- Extensive range of accessories

Ploughshare® batch mixer type FKM LS

- Newest member of the LÖDIGE program

- Attractive price

- Short delivery time

- “Made in Germany”

- Same manufacturing quality, performance and mixing results as the classic LÖDIGE mixer

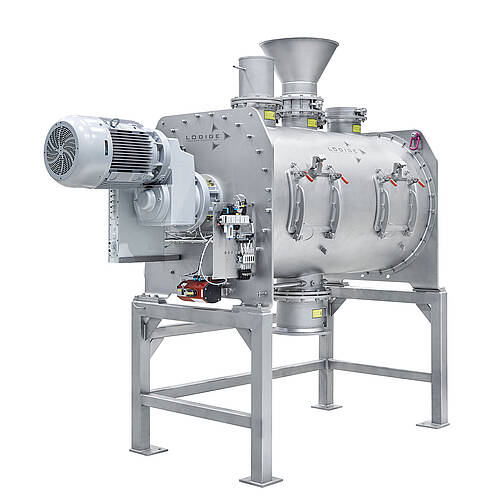

Ploughshare® Mixers for batch operation "Hygienic Design"

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

Ploughshare® Mixers for batch operation "Universal Design"

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

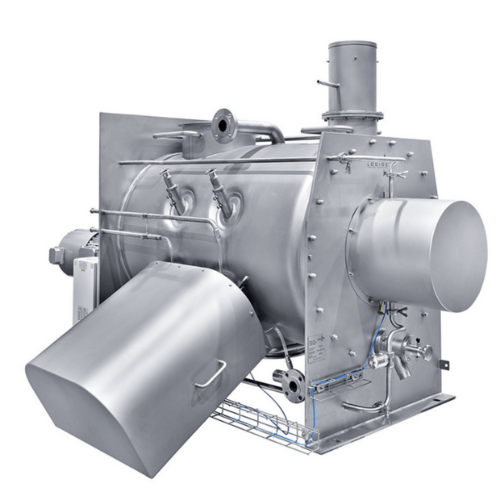

Ploughshare® mixers for continuous operation "Universal Design"

- Excellent homogeneity of the final product

- Retention/mixing times and granulation processes can be adapted to the specific product

- Gentle product treatment

- Consistent reproducibility

- High availability

- Easy accessibility of all internal mixer components

- Low-maintenance mixer concept

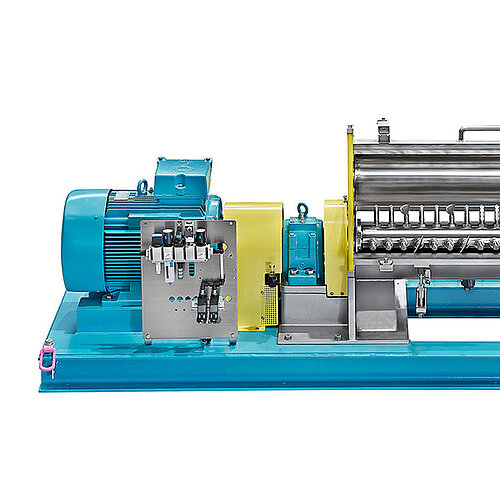

Ringlayer mixer CoriMix® for continuous operation

- Compact machine unit with high throughput

- Extremely high mixing homogeneity

- Versatile application options

- Easy operation and cleaning

- High operating reliability and service life

NO SUITABLE MACHINE FOUND?

WE ARE CERTIFIED & APPROVED

Our commitment to quality is officially confirmed by recognised testing bodies. Find out more here about our industry-specific approvals and certificates.

HOW CAN

WE HELP?

We make it easy for you to find the right contact for your specific needs and questions. Whether you need detailed product information, technical support or advice, our experienced team is ready to help you with tailored solutions.