HORIZONTAL GRANULATION IN LÖDIGE MACHINES

Granulation is an important process in many industries. Granulation involves mixing fine particles together and converting them into larger, granular forms by adding binders or by applying moisture and then drying. This process is of particular importance in industries such as pharmaceuticals, food, plastics, environmental technology, building materials and medicine. Products processed in the granulation sector include tablets, agglomerates, plastics, minerals, detergents and animal feed. LÖDIGE has established itself as a leading supplier in this field of expertise: Our solutions are characterised by continuous innovation, a high level of quality and experienced customer service.

THE LÖDIGE GRANULATION PROCESS

- Mixing:

To achieve a homogeneous mix, the powder particles are first thoroughly mixed in the mixing drum. - Moisture addition:

A defined amount of liquid (such as water, oil or a binder) can then be added to slightly wet the particle surface and promote granulation. - Agglomeration:

The moistened particles begin to adhere to each other and form larger agglomerates or granules under the mixing effect of the Ploughshare® Shovels. The intensity of the movement and the geometry of the mixing elements assist this process. - Drying (if necessary):

Once granules have been formed, the next step may be to dry them to remove excess moisture and achieve the desired strength and size of the granules.

GRANULATION IN A HORIZONTAL MIXER

Horizontal granulation with LÖDIGE systems offers many advantages. This technology enables uniform mixing and granulation, which are decisive for the quality and homogeneity of the end product. Applications are found in the processing of plastics, minerals, starch, dust, detergents and in the production of agglomerates. The horizontal arrangement of the mixing drum ensures efficient movement of the product and the best possible processes.

GRANULATION IN HORIZONTAL MIXING UNITS

Both horizontal and vertical mixers have their own specific advantages and fields of application, which are selected according to the requirements of the granulation process and the properties of the materials to be processed. The choice between a horizontal and a vertical mixer depends on several factors such as the physical properties of the raw materials, the production capacity required, the space available in the plant and the specific requirements of the end product. In some cases the most effective solution may be a combination of both types of mixer or the use of a specific mixer. The advantages of horizontal systems are:

- Uniform mixing:

Horizontal mixing units such as Ploughshare® Mixers are well known for their ability to produce a very uniform mix. This is particularly important where the quality of the end product is highly dependent on the homogeneity of the mix. - Scalability:

Horizontal mixers can be manufactured in very large sizes, making them suitable for high volume industrial applications. - Flexibility:

The mixers can be equipped with various mixing elements and other features to increase the efficiency of the granulation process, such as choppers or spray nozzles for the addition of binders.

OUR SOLUTIONS FOR GRANULATION IN A HORIZONTAL SYSTEM

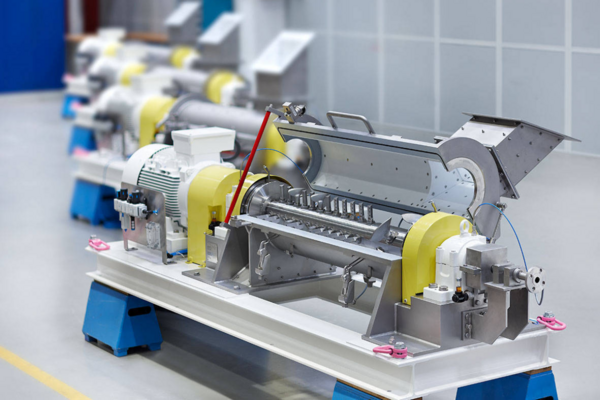

Innovative machines for optimum results - LÖDIGE has a range of horizontal machines that are tailored to meet your granulation needs. Our machines are well-known for their performance, reliability and gentle treatment of the mixed product. Our horizontal granulation machines are the following:

Ploughshare® Mixer (Laboratory machine)

- Guaranteed LÖDIGE quality

- Attractive value for money

- Functional design

- Ideal for your product and process development

- Extensive range of accessories

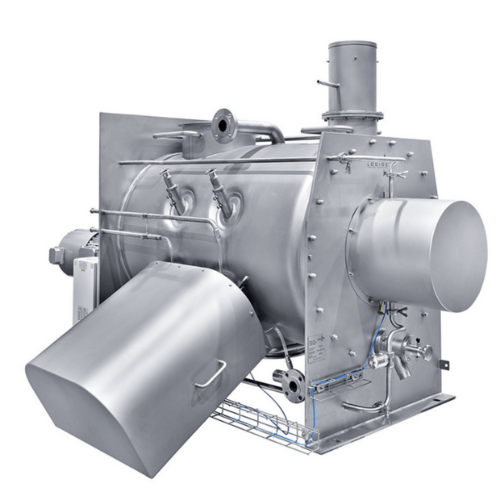

Ploughshare® Mixers for batch operation "Hygienic Design"

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

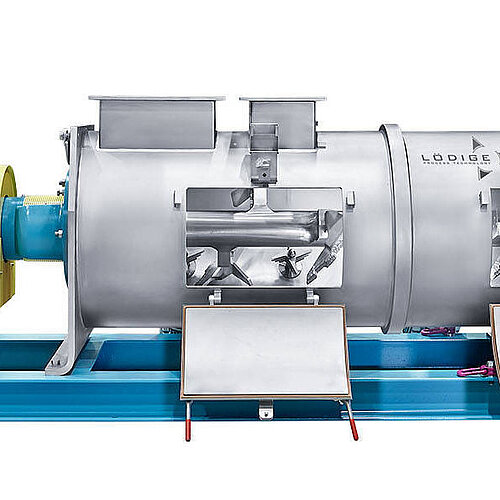

Ploughshare® Mixers for batch operation "Universal Design"

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

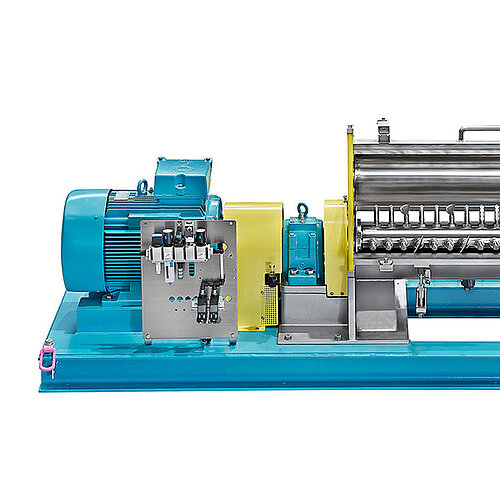

Ploughshare® mixers for continuous operation "Universal Design"

- Excellent homogeneity of the final product

- Retention/mixing times and granulation processes can be adapted to the specific product

- Gentle product treatment

- Consistent reproducibility

- High availability

- Easy accessibility of all internal mixer components

- Low-maintenance mixer concept

Ringlayer mixer CoriMix® for continuous operation

- Compact machine unit with high throughput

- Extremely high mixing homogeneity

- Versatile application options

- Easy operation and cleaning

- High operating reliability and service life

NO SUITABLE MACHINE FOUND?

FULL RANGE OF SERVICES RELATED TO GRANULATION

In addition to highly developed machines, LÖDIGE offers a wide range of services. These include customised engineering solutions, the manufacture of pressure vessels, comprehensive quality assurance systems and turnkey solutions. This range of services guarantees our customers comprehensive support - from planning to commissioning of the granulation systems.

WE ARE CERTIFIED & APPROVED

Our commitment to quality is officially confirmed by recognised testing bodies. Find out more here about our industry-specific approvals and certificates.

HOW CAN WE HELP?

We make it easy for you to find the right contact for your specific needs and questions. Whether you need detailed product information, technical support or advice, our experienced team is ready to help you with tailored solutions.