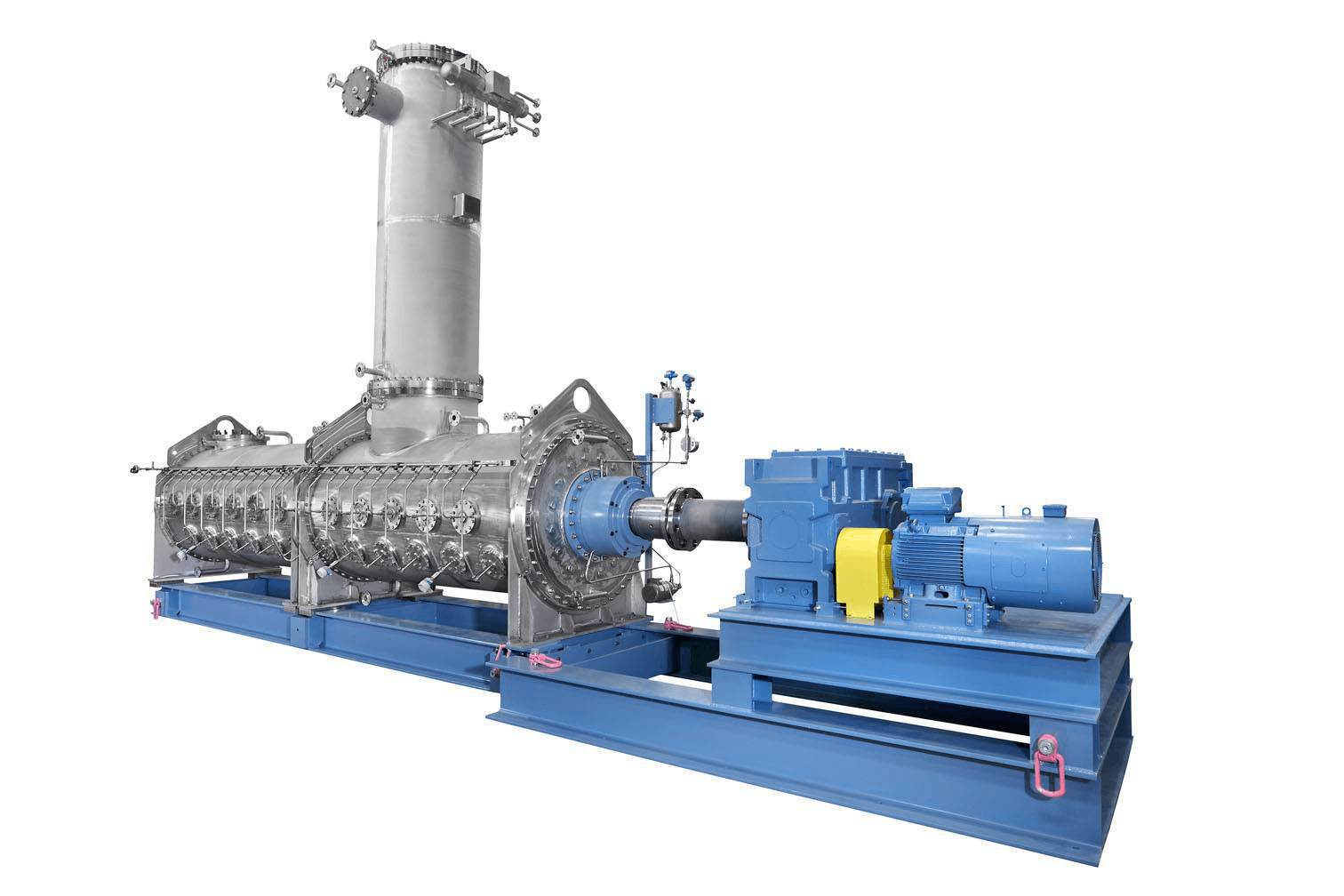

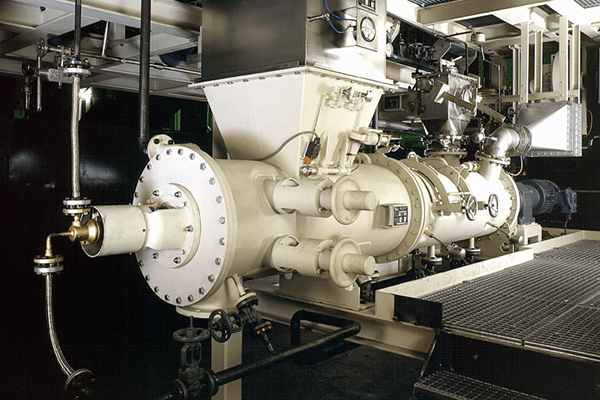

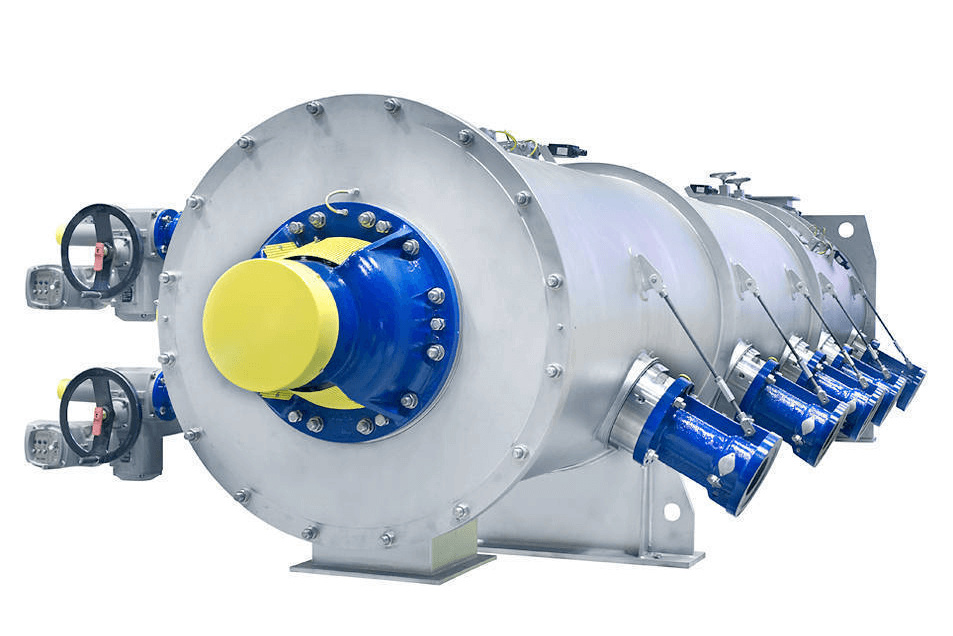

LÖDIGE'S GRANULATION DRYER DRUVATHERM® FOR CONTINUOUS OPERATION

- Combination of convection and contact drying

- Process management at low temperatures

- Gentle product treatment

- Simultaneous product granulation possible

- Reliable reproducibility of product quality

- Suitable for stripping processes

- High system availability

MACHINE TYPE

The granulation dryer is designed for continuous operation. A unique property of this dryer is its combination of convection and contact drying. Adaptation of the retention time to the specific process ensures that products are dried at low temperatures, i.e. gently. At the same time, excellent granulation of the final product can be achieved. The continuous granulation dryer is particularly suitable for drying and product formulation of substances with problematic flow characteristics and a changing consistency (multi-phase process).

We develop customised solutions, adapted and optimised perfectly for your application and product, and designed for long-term use in production for any of your tasks. A consistent process design and extensive basic engineering guarantee an economic overall solution.

The granulation dryer uses the fluid bed principle introduced by Lödige to industrial mixing technology, meaning it uses the entire mechanically generated “fluid bed” to support the drying process.

This intense mixing effect separates the particles in the fluid bed, thereby creating a large product surface and preventing the generation of temperature and moisture gradients in the product bed. This leads to a significant increase in the heat exchange via the heated drum walls.

The product behaviour during drying is affected by the mixing tool geometry and choppers rotating at high speed which can be activated as an option; these can be used to control the average product retention time and the retention time distribution. It is therefore possible to achieve a defined grain size distribution during granulation processes..

The system permits both contact drying under normal pressure or in an inert atmosphere and convection/contact drying in co-current and counter-current flow.

Thermal energy is applied through the jacket surfaces and high-temperature gases.

Downloads

WE ARE CERTIFIED & APPROVED

Our commitment to quality is officially confirmed by recognised testing bodies. Find out more here about our industry-specific approvals and certificates.

LET'S HAVE A CHAT

Do you have any questions, suggestions or feedback? Let us know your request using the contact form and we will get back to you as soon as possible: