THE LÖDIGE HIGH-SPEED GRANULATOR

- Versatile application options for the pharmaceutical and food industry

- GMP-compliant design

- Usable as a single unit or combined with a cooling mixer

- User-friendly control system with pre-defined process steps

- Many additional options available (CIP system, qualification, etc.)

MACHINE TYPE

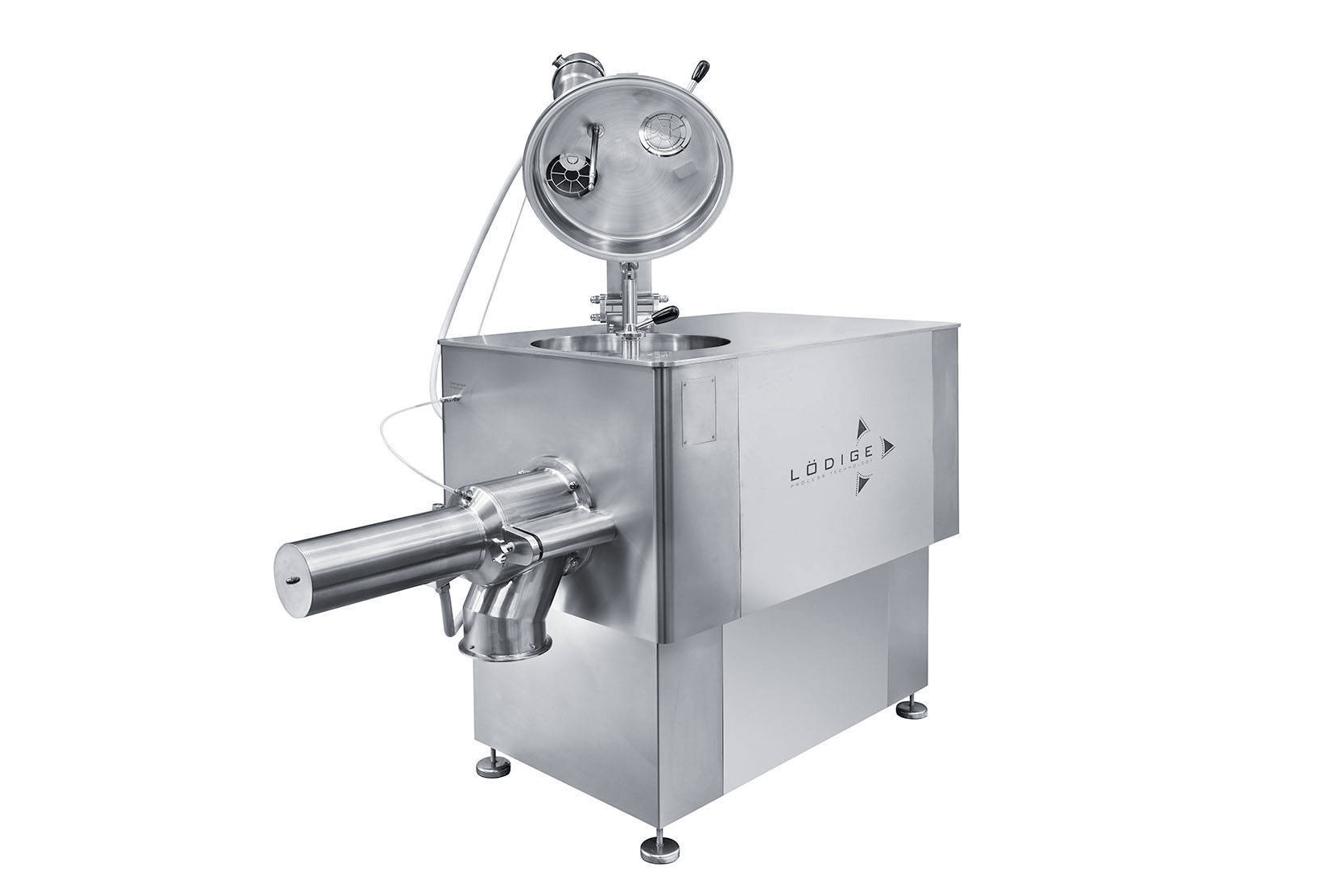

The high-speed mixer/granulator represents the GMP-compliant development of the heating mixer. The high-speed granulator, which operates according to a friction mixer principle, is particularly suitable for granulation processes induced by binders melting, treatment of pharmaceutical PVC compounds and many other pharmaceutical and food applications. The high-speed granulator can be operated both as a single unit and in combination with a cooling mixer.

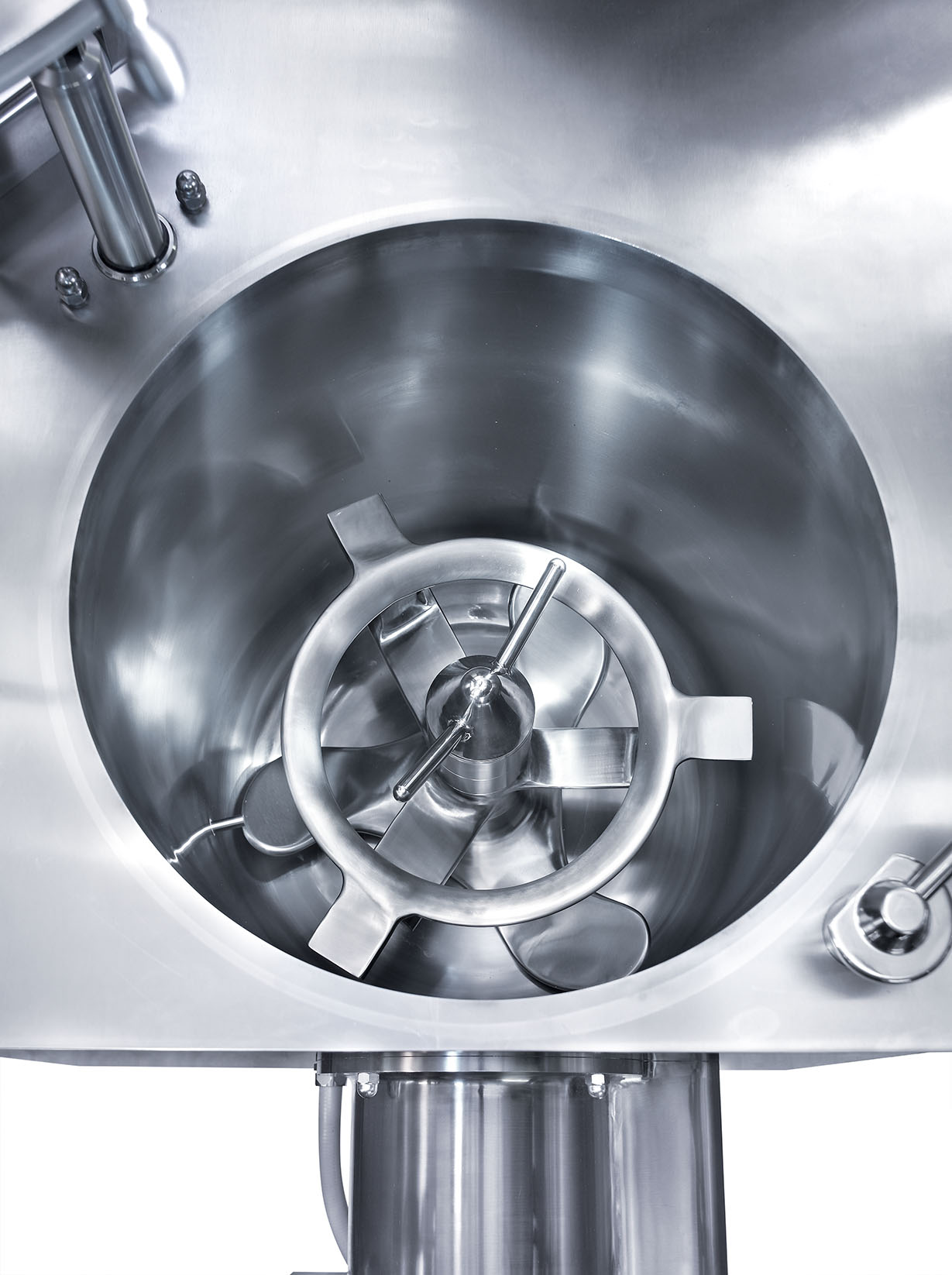

The geometrically designed high-speed mixing tool accelerates the product both radially, so that it is pushed outward and in a spiralling upward movement, creating a distinct vortex shape. The combination of this three-dimensional product movement with intense friction application ensures systematic and even heating of the entire batch, permitting granulation processes induced by binders melting in addition to other procedures.

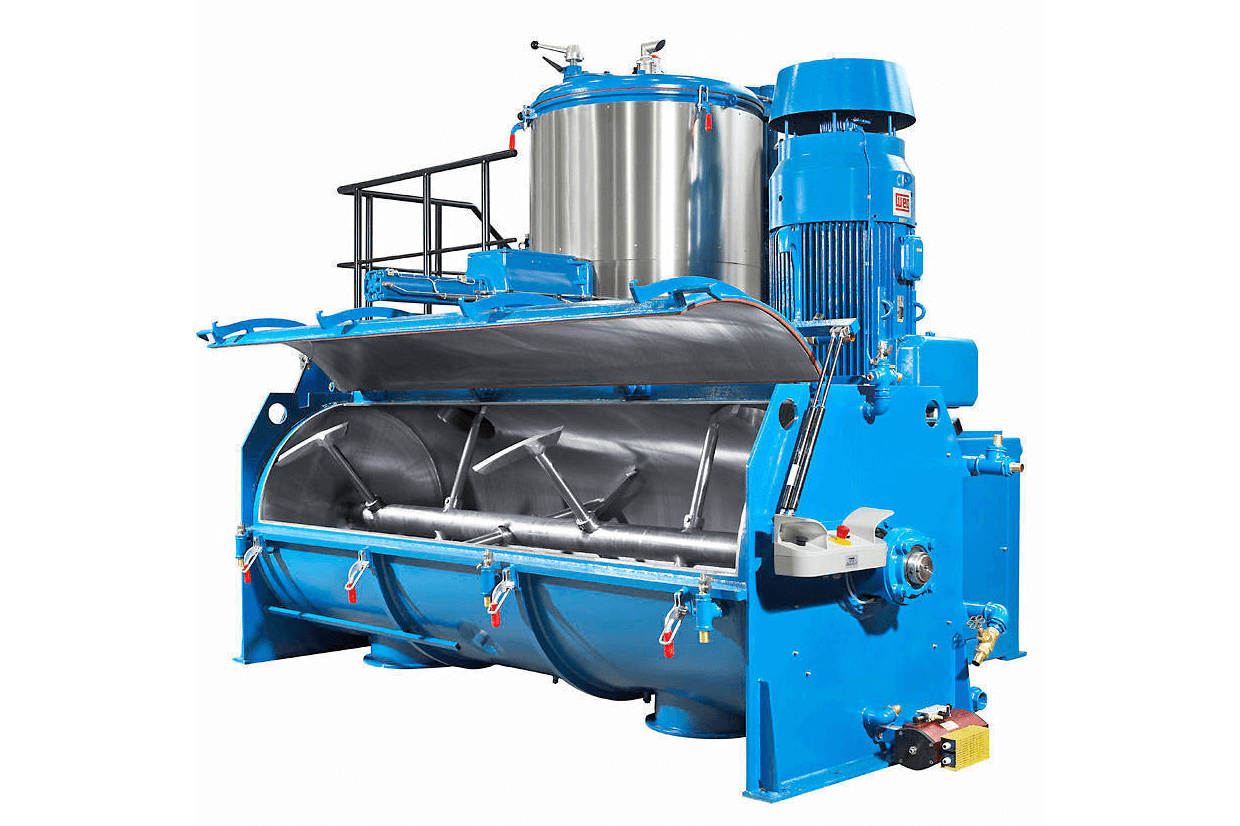

The available mixing tools are either a circular upper impeller or a blade tool, which can be selected based on the process and products. Downstream vertical and horizontal cooling mixers can be used for gentle cooling of the heated mix to the required final temperature. Moreover, it is possible to combine several prepared products from the LMG to form one batch in the cooling mixer. The heating-cooling mixer combination is always designed for the specific application based on the required process parameters.

The high-speed granulator is designed to be GMP-compliant and consists completely of stainless steel, both as a single unit and in combination with a cooling mixer. A black-and-white separation of the machine line is possible. As an option, a control system suitable for pharmaceutical applications, a CIP cleaning system and qualification documentation are available. Additional special designs can be implemented as agreed.

WE ARE CERTIFIED & APPROVED

Our commitment to quality is officially confirmed by recognised testing bodies. Find out more here about our industry-specific approvals and certificates.

LET'S HAVE A CHAT

Do you have any questions, suggestions or feedback? Let us know your request using the contact form and we will get back to you as soon as possible: