LÖDIGE'S VACUUM SHOVEL DRYER DRUVATHERM® (LABORATORY MACHINE)

- Reliable scale-up

- Production development under consideration of industrial factors

- “All-in-one process” (mixing, granulation, drying, cooling)

- Intense mixing prevents temperature and moisture gradients within the product

- Short drying times through intense product movement and effective application of thermal energy

- Gentle thermal treatment at low temperatures using a strong vacuum

- Cost-efficient solvent recovery

MACHINE TYPE

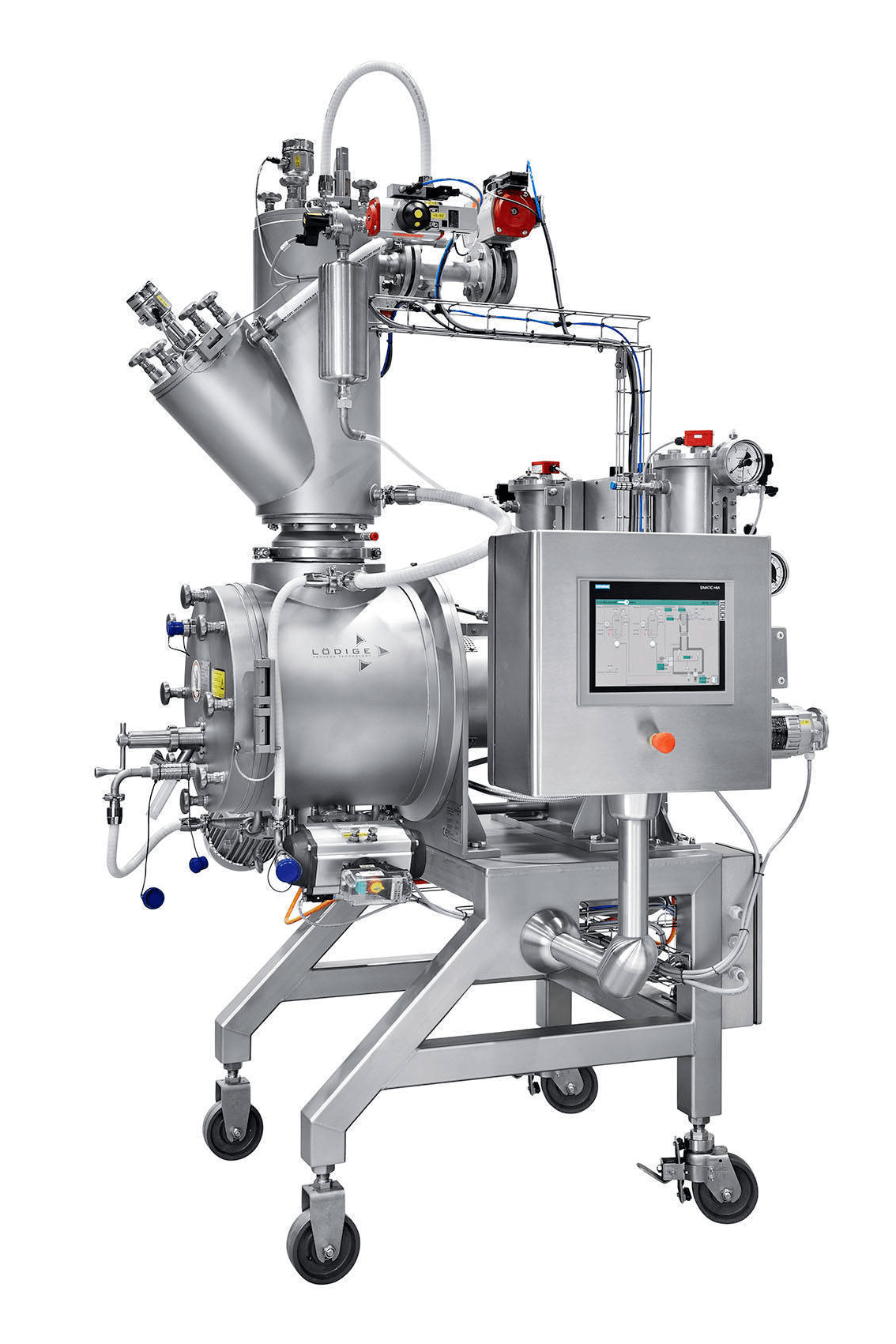

The design of the laboratory vacuum shovel dryer DRUVATHERM® offers users a universal machine with regard to ergonomics, machine technology and process engineering options. The system provides reliable scale-up to production scales in the context of product and process development and can likewise be used for small batch production. The laboratory dryer is suitable for drying suspensions, pastes, bulk goods and powders.

The Lödige laboratory vacuum shovel dryer DRUVATHERM® is a horizontal, batch vacuum dryer with a frequency-controlled mixing tool. This mixer consisting of mixing elements adapted to the process and arranged on a shaft according to a specific system - is installed in a cylindrical mixing drum equipped with a temperature control jacket. Rotation of the mixing unit generates a three-dimensional product movement, in which all of the product is constantly in motion. The contact frequency of particles with the heat exchange surface (heated wall of the device) generated by this mechanically generated fluid bed leads to shorter drying times.

The chopper rotating at high speeds fitted to the side of the mixing drum is used to disperse the product during transition between phases (lumpy/grainy/powdered). Product surfaces are opened up during this process. This leads to a significant increase in drying capacity and prevents moisture and temperature gradients. Fine particles pulled along by solvent vapours are separated in the filter and returned to the product bed through pneumatic filter cleaning.

- Mixing drum surfaces with industrial polishing on the outside

- Surfaces in contact with product electrolytically polished

- Technical systems completely encased - laterally movable housing provides easy and good accessibility

- Integrated control system

- Double-acting mechanical seal

- Parts in contact with the product available in special materials

- GMP standard/chemical design

- Drum sizes of 5, 10 and 20 l available

- Available as a machine with internal pressure

APPLICATION FIELDS

Trouble finding your industry?

Downloads

WE ARE CERTIFIED & APPROVED

Our commitment to quality is officially confirmed by recognised testing bodies. Find out more here about our industry-specific approvals and certificates.

LET'S HAVE A CHAT

Do you have any questions, suggestions or feedback? Let us know your request using the contact form and we will get back to you as soon as possible: