WHERE INDUSTRIAL HISTORY SHAPE WELCOME TO LÖDIGE

We are the world's leading supplier for process equipment and systems for applications requiring process technology and the inventor of the original Ploughshare® Mixer.

We have outstanding expertise in the fields of mixing, granulating, reacting, drying and coating. Our expertise covers ten key industries in particular: building materials, chemicals, cosmetics, plastics, metallurgy, batteries, food, pharmaceuticals, polysaccharides and environmental technology. We are also happy to serve other industries with our customer-orientated quality focus. Please feel free to contact us!

LÖDIGE MACHINES: QUALITY IN EVERY PROCESS

From mixing and granulating to coating, drying and reacting - our machines ensure not only the highest quality and efficiency, but also sustainability and cost-effectiveness.

YourYour contact for the industry:

Our solutions for your project

Looking for a complete solution customised to your needs?

We offer process technology, system integration and mechanical engineering from a single source. Let us talk about the development of a customised solution: we can provide you with a turnkey solution.

No suitable machine found for your selection!

YourYour contact for the industry:

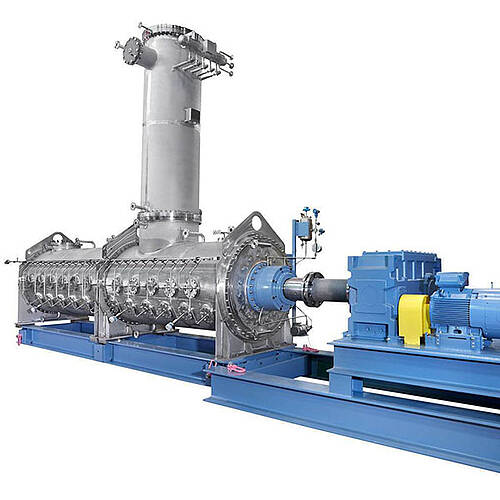

Granulation dryer DRUVATHERM® for continuous operation

- Combination of convection and contact drying

- Process management at low temperatures

- Gentle product treatment

- Simultaneous product granulation possible

- Reliable reproducibility of product quality

- Suitable for stripping processes

- High system availability

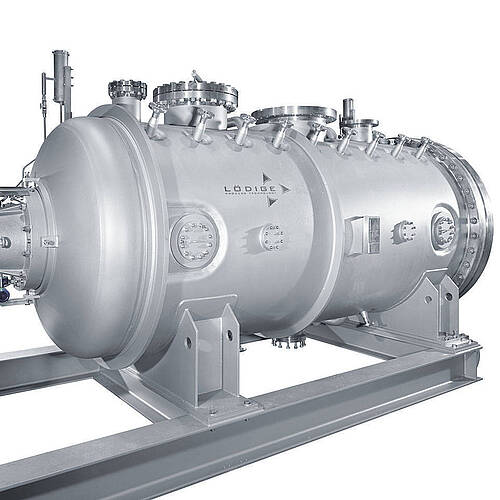

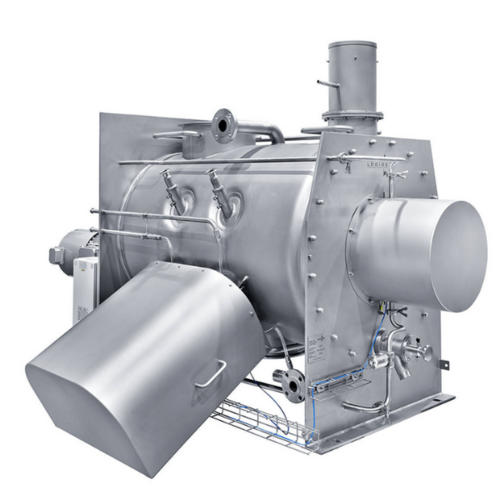

Vacuum shovel dryer DRUVATHERM®

- Intense mixing prevents temperature and moisture gradients within the product

- Maximum heat transfer coefficients ensure excellent dryer performance

- Gentle thermal product treatment in vacuum mode

- Multi-phase process (mixing, granulation, drying, cooling)

- Cost-efficient solvent recovery

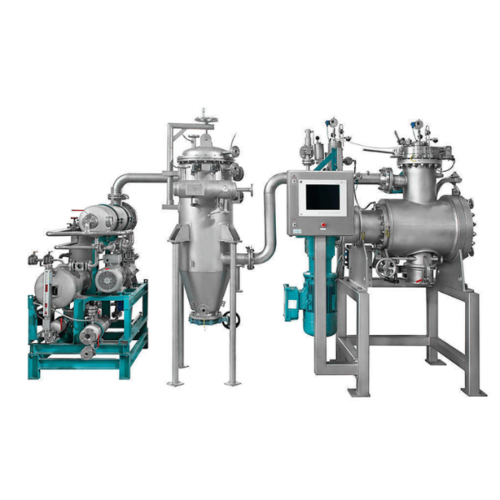

Vacuum shovel dryer DRUVATHERM® (Lab machine)

- Reliable scale-up

- Production development under consideration of industrial factors

- “All-in-one process” (mixing, granulation, drying, cooling)

- Intense mixing prevents temperature and moisture gradients within the product

- Short drying times through intense product movement and effective application of thermal energy

- Gentle thermal treatment at low temperatures using a strong vacuum

- Cost-efficient solvent recovery

The wet mixer

- High mixing quality even for critical products

- Application of high shearing forces

- Easy operation and cleaning

- Reliable and time-tested mixer concept

THE LÖDIGE MIXING GRANULATOR

- Mixing granulator for pharmaceutical products, cosmetics and food

- GMP-compliant design

- Modular WIP system for the machine and all additional components

- Automatic liquid addition in different versions

- New pharmaceutical controls

- Temperature control jacket for heating/cooling

- Integrated sieve on machine outlet

- Vacuum feeder

- Customised ATEX concepts

Mixing granulator (Laboratory machine)

- Laboratory mixing granulator with exchangeable vessel

- Mixing, granulation and temperature control in one machine

- Exchangeable vessels with a volume of 1, 5, 10 or 15 l

- GMP-compliant design

- User-friendly, integrated control system

- Operation-ready system

Ploughshare® Mixer (Laboratory machine)

- Guaranteed LÖDIGE quality

- Attractive value for money

- Functional design

- Ideal for your product and process development

- Extensive range of accessories

The Lödige high-speed granulator

- Versatile application options for the pharmaceutical and food industry

- GMP-compliant design

- Usable as a single unit or combined with a cooling mixer

- User-friendly control system with pre-defined process steps

- Many additional options available (CIP system, qualification, etc.)

Ringlayer mixer CoriMix® for continuous operation

- Compact machine unit with high throughput

- Extremely high mixing homogeneity

- Versatile application options

- Easy operation and cleaning

- High operating reliability and service life

LÖDIGE Coater LC

- Filling level variability without drum replacement

- The extremely low height of the mixing elements permits a high degree of filling level variability.

- Even application and short process times

- The high number of mixing elements and nozzles ensures ideal distribution and leads to low variance in the evenness of application.

- High-speed = Time is money

- The even air distribution throughout the entire drum length ensures that the drying effectiveness is high and permits high spray rates.

- Optimised air routing: A quality improvement

- This air routing prevents spray drying, increases service life for campaign production and reduces the cleaning workload.

- Simple cleaning

- A sophisticated cleaning system and its great mechanical effect make cleaning quick and efficient. This saves time, cleaning agents and energy.

LÖDIGE Coater LC LAB (Laboratory machine)

- Innovative design, great functionality

- Variable filling level between 0.6 and 6.0 l

- High process speed due to high spray rates and high drying capacity

- Even distribution of the suspension

- Process conditions comparable to Lödige production coaters

- User-friendly: Easy handling, intuitive operation

Reactor DRUVATHERM®

- Rapid uniting of reacting agents

- Prevention of local overconcentrations

- No temperature gradients within the reaction field

- Improved conversion of reactin agents, leading to higher yield with greater purity of the final product

- Multi-phase process (reaction, heating, drying, granulation, cooling)

Reactor DRUVATHERM® (Laboratory machine)

- DRUVATHERM® reactor at laboratory scale

- Rapid uniting of reacting agents

- Prevention of local overconcentrations

- No temperature gradients within the reaction field

- Improved conversion of reacting agents, leading to higher yield with greater purity of the final product

- Multi-phase proceess (reaction, heating, drying, granulation, cooling)

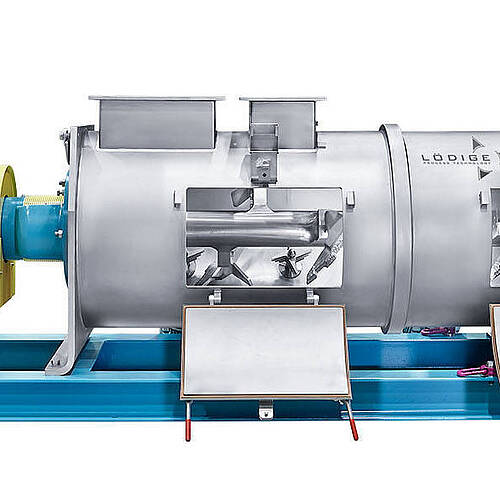

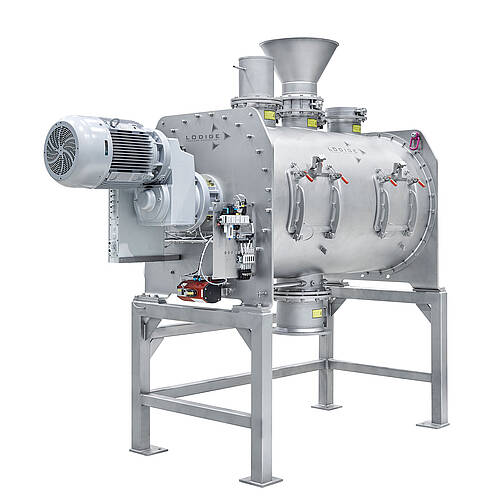

Ploughshare® mixers for continuous operation "Universal Design"

- Excellent homogeneity of the final product

- Retention/mixing times and granulation processes can be adapted to the specific product

- Gentle product treatment

- Consistent reproducibility

- High availability

- Easy accessibility of all internal mixer components

- Low-maintenance mixer concept

Ploughshare® Mixers for batch operation "Hygienic Design"

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

Ploughshare® Mixers for batch operation "Universal Design"

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

Ploughshare® batch mixer type FKM LS

- Newest member of the LÖDIGE program

- Attractive price

- Short delivery time

- “Made in Germany”

- Same manufacturing quality, performance and mixing results as the classic LÖDIGE mixer

NEWS AT LÖDIGE

Discover the latest news, most exciting updates and most recent updates.

WE ARE CERTIFIED & APPROVED

Our commitment to quality is officially confirmed by recognised testing bodies. Find out more here about our industry-specific approvals and certificates.

GET IN NOW AND GET INVOLVED

As a globally active family business from the SME sector, our values are rooted in tradition - but our eyes are always on the future. We not only offer a stable working environment, but also the opportunity to develop an international company and grow together. With pleasure also with you!

GLOBAL PLAYER & REGIONAL

ROOTED FAMILY BUSINESS

LET'S HAVE A CHAT

Do you have any questions, suggestions or feedback? Let us know your request using the contact form and we will get back to you as soon as possible: