EFFICIENT CONTACT DRYING MADE BY LÖDIGE

In the world of industrial drying processes, the name LÖDIGE stands for quality, efficiency and innovation. Our contact dryers are benchmark technology using the latest techniques for industrial drying. We supply not only to the cosmetic, chemical and pharmaceutical industries, but also to the environmental and plastics sectors. Our solutions are proven all over the world.

CONTACT DRYING: ONE PROCESS, MANY ADVANTAGES

Contact drying is a highly effective process for removing moisture from products. It is based on the principle of direct contact between the moist product and a hot surface, resulting in rapid evaporation of the moisture. Unlike other drying methods where heat is transferred indirectly, contact drying allows heat energy to be transferred directly to the product.

It also allows precise control of the entire drying process. This is particularly important to ensure even drying of the product and to avoid overheating or damage. Contact drying is suitable for a wide range of products such as food, powders, granules or liquids. LÖDIGE contact dryers, such as the DRUVATHERM® Vacuum Shovel Dryer, make optimum use of these principles and offer the following advantages:

- High energy efficiency: Direct heat transfer reduces energy loss.

- Quick drying: Direct heat transfer provides faster drying times, ideal for temperature sensitive products.

- Compact design: Our dryers are designed to save space and fit into tight production environments

- Low risk of contamination: Closed systems reduce the risk of product contamination.

CONTINUOUS OPERATION VS. BATCH OPERATION

LÖDIGE provides both contact drying systems for continuous and batch operations. Each process has its specific applications and advantages. The continuous drying process is ideal for processing large quantities with consistent quality. Our continuous Granulation Dryer combines convection and contact drying for efficient drying at low temperatures.

On the other hand, discontinuous operation offers optimum flexibility for batch processes and a wide range of product types. With the innovative LÖDIGE Shovel Dryer, processes can be adapted to different requirements in a flexible manner. Both systems operate according to the fluid bed principle generated mechanically and first developed by LÖDIGE: this ensures intensive product movement and therefore efficient drying.

CONTACT DRYING ALWAYS THINKING AHEAD

The fluid bed principle developed by LÖDIGE is an innovation in the field of drying technology. This mixing principle combines the efficiency of centrifugal force with the vortex movement to ensure uniform and effective drying.

By implementing this process in our contact dryers, the product to be dried is set into an intensive three-dimensional movement. This greatly increases the frequency of contact between the product and the heated surface, resulting in very short drying times.

The fluid bed principle not only ensures improved heat transfer and efficient use of energy, but also minimises the risk of product damage and guarantees a high-quality end product. The use of this process in LÖDIGE contact dryers such as the DRUVATHERM® Vacuum Shovel Dryer enables gentle thermal treatment of products at low temperatures and under vacuum. This is particularly advantageous for temperature sensitive or perishable products.

THE LÖDIGE CONTACT DRYERS

At LÖDIGE we understand that each application is unique. That is why we don't just offer standard solutions but work closely with our customers to develop drying systems meeting your specific requirements. Discover all LÖDIGE contact dryers below:

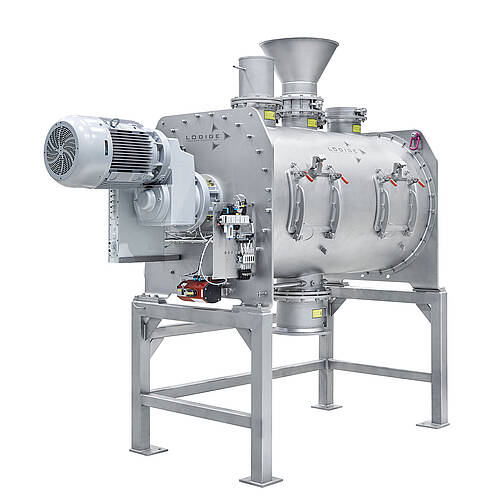

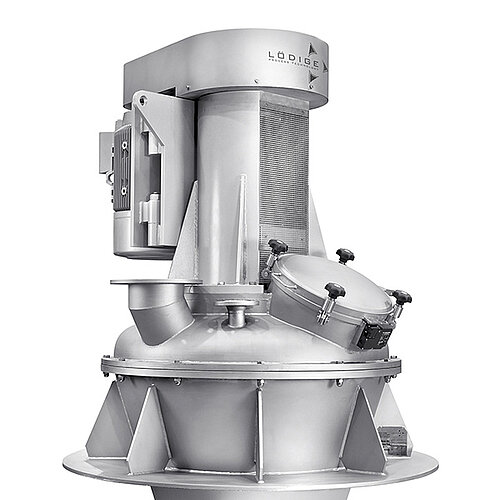

Granulation dryer DRUVATHERM® for continuous operation

- Combination of convection and contact drying

- Process management at low temperatures

- Gentle product treatment

- Simultaneous product granulation possible

- Reliable reproducibility of product quality

- Suitable for stripping processes

- High system availability

Mixing granulator (Laboratory machine)

- Laboratory mixing granulator with exchangeable vessel

- Mixing, granulation and temperature control in one machine

- Exchangeable vessels with a volume of 1, 5, 10 or 15 l

- GMP-compliant design

- User-friendly, integrated control system

- Operation-ready system

Ploughshare® Mixer (Laboratory machine)

- Guaranteed LÖDIGE quality

- Attractive value for money

- Functional design

- Ideal for your product and process development

- Extensive range of accessories

Ploughshare® batch mixer type FKM LS

- Newest member of the LÖDIGE program

- Attractive price

- Short delivery time

- “Made in Germany”

- Same manufacturing quality, performance and mixing results as the classic LÖDIGE mixer

Ploughshare® Mixers for batch operation "Hygienic Design"

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

Ploughshare® Mixers for batch operation "Universal Design"

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

Ploughshare® mixers for continuous operation "Universal Design"

- Excellent homogeneity of the final product

- Retention/mixing times and granulation processes can be adapted to the specific product

- Gentle product treatment

- Consistent reproducibility

- High availability

- Easy accessibility of all internal mixer components

- Low-maintenance mixer concept

Reactor DRUVATHERM®

- Rapid uniting of reacting agents

- Prevention of local overconcentrations

- No temperature gradients within the reaction field

- Improved conversion of reactin agents, leading to higher yield with greater purity of the final product

- Multi-phase process (reaction, heating, drying, granulation, cooling)

Reactor DRUVATHERM® (Laboratory machine)

- DRUVATHERM® reactor at laboratory scale

- Rapid uniting of reacting agents

- Prevention of local overconcentrations

- No temperature gradients within the reaction field

- Improved conversion of reacting agents, leading to higher yield with greater purity of the final product

- Multi-phase proceess (reaction, heating, drying, granulation, cooling)

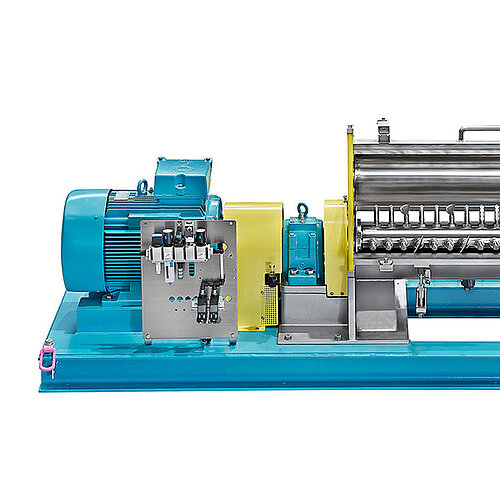

Ringlayer mixer CoriMix® for continuous operation

- Compact machine unit with high throughput

- Extremely high mixing homogeneity

- Versatile application options

- Easy operation and cleaning

- High operating reliability and service life

The Lödige high-speed granulator

- Versatile application options for the pharmaceutical and food industry

- GMP-compliant design

- Usable as a single unit or combined with a cooling mixer

- User-friendly control system with pre-defined process steps

- Many additional options available (CIP system, qualification, etc.)

THE LÖDIGE MIXING GRANULATOR

- Mixing granulator for pharmaceutical products, cosmetics and food

- GMP-compliant design

- Modular WIP system for the machine and all additional components

- Automatic liquid addition in different versions

- New pharmaceutical controls

- Temperature control jacket for heating/cooling

- Integrated sieve on machine outlet

- Vacuum feeder

- Customised ATEX concepts

The wet mixer

- High mixing quality even for critical products

- Application of high shearing forces

- Easy operation and cleaning

- Reliable and time-tested mixer concept

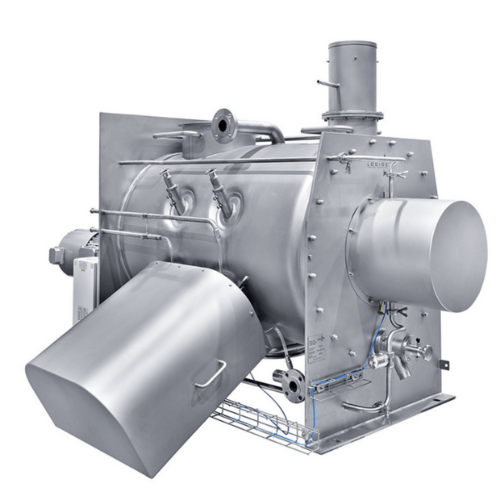

Vacuum shovel dryer DRUVATHERM®

- Intense mixing prevents temperature and moisture gradients within the product

- Maximum heat transfer coefficients ensure excellent dryer performance

- Gentle thermal product treatment in vacuum mode

- Multi-phase process (mixing, granulation, drying, cooling)

- Cost-efficient solvent recovery

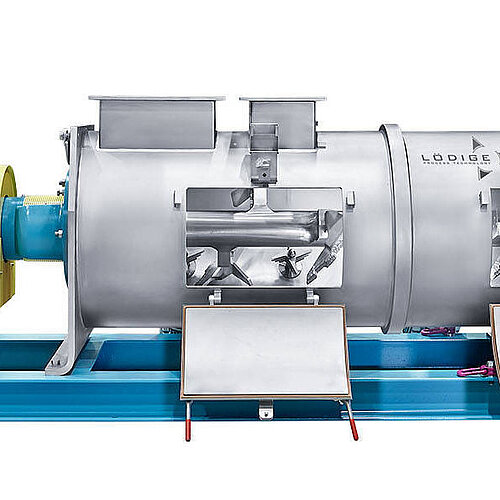

Vacuum shovel dryer DRUVATHERM® (Lab machine)

- Reliable scale-up

- Production development under consideration of industrial factors

- “All-in-one process” (mixing, granulation, drying, cooling)

- Intense mixing prevents temperature and moisture gradients within the product

- Short drying times through intense product movement and effective application of thermal energy

- Gentle thermal treatment at low temperatures using a strong vacuum

- Cost-efficient solvent recovery

NO SUITABLE MACHINE FOUND?

VERSATILE DRYING TECHNOLOGY FOR A WIDE RANGE OF INDUSTRIES

Our contact dryers are successful across all sectors - from cosmetics to chemicals, pharmaceuticals, the environment and plastics.

In the cosmetic industry, our contact dryers provide efficient and gentle drying of products such as creams, lotions and make-up. By precisely controlling drying parameters, we can ensure that products retain their desired consistency and quality.

In the chemical industry, our solutions are used to dry chemical compounds and materials. By precisely controlling temperature and airflow, we achieve fast and efficient drying without affecting the chemical composition of the products.

In the pharmaceutical industry, LÖDIGE contact dryers play an important role in the production of medicines. They enable gentle drying of active ingredients and help to ensure the stability and efficacy of medicines.

In the environmental sector for example, our contact dryers are used to dry sewage sludge to reduce its volume and enable safe disposal. Our dryers can be heated directly or indirectly with a wide range of media and can handle viscoplastic product phases. In a vacuum, the boiling point of water or organic solvents is lowered for gentle, energy-saving drying.

We also offer customised solutions for the plastics industry. Our contact dryers enable efficient drying of plastic granules to reduce their moisture content and ensure optimum processing. This helps to improve product quality and reduce waste.

WE ARE CERTIFIED & APPROVED

Our commitment to quality is officially confirmed by recognised testing bodies. Find out more here about our industry-specific approvals and certificates.

THE NEXT STEP TO CUSTOMISED DRYING

Our drying solutions ensure not only excellent drying results, but also economical solvent recovery. They are suitable for all stages of product development, from laboratory to production scale. Trust LÖDIGE when it comes to advanced and reliable contact drying technologies. Contact us to find out how our drying technologies can improve your production efficiency.