VERSATILE SOLUTIONS FOR THE

CHEMICAL INDUSTRY

The chemical industry is the backbone of our modern life. Our daily life would be unimaginable without its diverse products - from cosmetics, paints and fertilisers to essential precursors for mechanical engineering, the food industry and much more. The process engineering solutions we develop are crucial for the efficiency and quality of these industries.

By developing advanced mixers as well as reaction and drying systems based on our many years of experience and continuous user feedback, we have achieved a leading position in the chemical industry. We are your partner for the economical, high-quality production and reproducibility of your products.

PRODUCTION CHALLENGES IN THE CHEMICAL INDUSTRY AND OUR RESPONSE

The chemical industry faces many challenges, including the mechanical treatment of products, the efficient drying of chemicals, the almost complete recovery of solvents and the implementation of high-temperature processes. Our drying systems, such as vacuum dryers, mixers and reactors, provide efficient solutions for these tasks.

We also meet complex requirements with innovative concepts such as the all-in-one-process. Mixing, liquid addition, heating, evaporation, reaction, drying, cooling, granulation and coating - thanks to the versatility of our reactors, the entire process chain can often be carried out in just one LÖDIGE machine.

SPECIAL APPLICATIONS REQUIRE SPECIAL SOLUTIONS

LÖDIGE process solutions are optimised for the respective products and their properties in terms of equipment size, consumption figures and materials. In this way, we support our customers in the chemical industry in the economic production of their indispensable products, such as:

- Methylcellulose derivatives

- Active pharmaceutical ingredients and intermediates

- Pectins, carrageenan, gellan as additives for foodstuffs

- Metal soaps (stearates)

- Plastic stabilisers

- Fibre and moulding compounds

- Sludges containing oil and solvent

- Friction materials

- Catalyst compounds

- Foodstuffs, vitamins, xanthan gum, cocoa masses

- Dyes, pigments

- Acid-modified starch

- Cationic starch

- Dextrins

- Gluten extraction

- Bioethanol production

LÖDIGE MACHINES

FOR THE CHEMICAL INDUSTRY

We provide machines specifically tailored to the respective process. Our range of machines extends from dry mixers for powders, fibres or granules to drying systems with condensate recovery and high-temperature reactors. This variety allows them to be used in different areas.

In addition, some LÖDIGE machines are even designed for several process steps within a single machine (all-in-one-process). An overview of the individual machines is given below:

Granulation dryer DRUVATHERM® for continuous operation

- Combination of convection and contact drying

- Process management at low temperatures

- Gentle product treatment

- Simultaneous product granulation possible

- Reliable reproducibility of product quality

- Suitable for stripping processes

- High system availability

Ploughshare® Mixer (Laboratory machine)

- Guaranteed LÖDIGE quality

- Attractive value for money

- Functional design

- Ideal for your product and process development

- Extensive range of accessories

Ploughshare® batch mixer type FKM LS

- Newest member of the LÖDIGE program

- Attractive price

- Short delivery time

- “Made in Germany”

- Same manufacturing quality, performance and mixing results as the classic LÖDIGE mixer

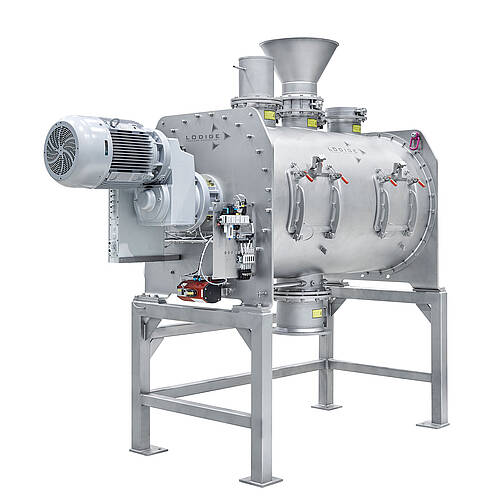

Ploughshare® Mixers for batch operation "Hygienic Design"

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

Ploughshare® Mixers for batch operation "Universal Design"

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

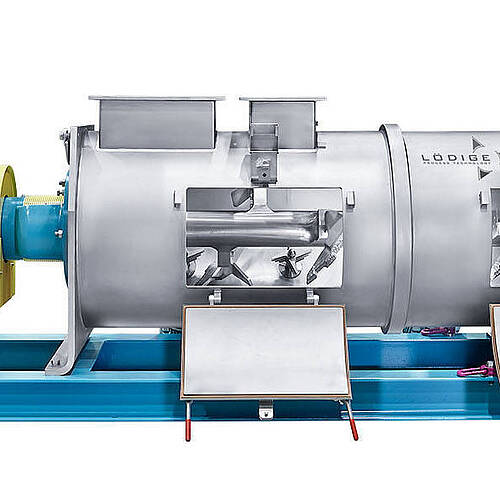

Ploughshare® mixers for continuous operation "Universal Design"

- Excellent homogeneity of the final product

- Retention/mixing times and granulation processes can be adapted to the specific product

- Gentle product treatment

- Consistent reproducibility

- High availability

- Easy accessibility of all internal mixer components

- Low-maintenance mixer concept

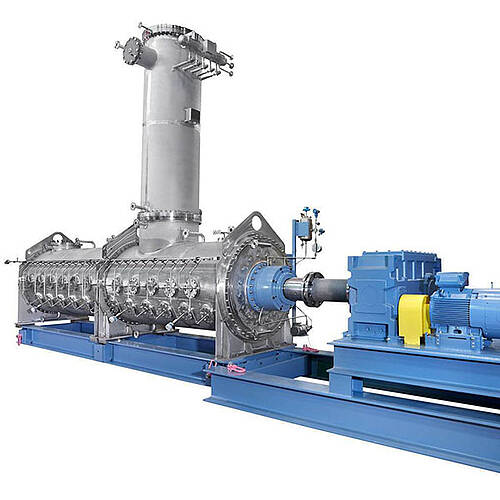

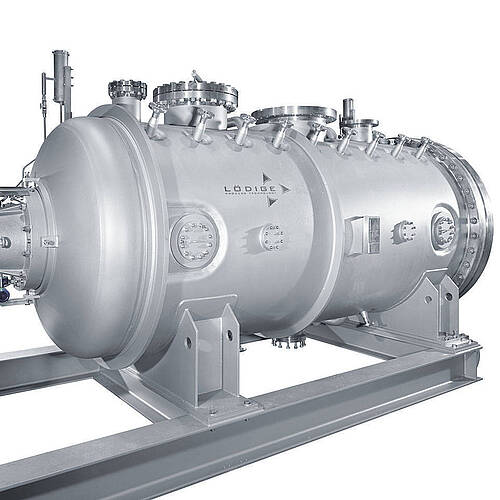

Reactor DRUVATHERM®

- Rapid uniting of reacting agents

- Prevention of local overconcentrations

- No temperature gradients within the reaction field

- Improved conversion of reactin agents, leading to higher yield with greater purity of the final product

- Multi-phase process (reaction, heating, drying, granulation, cooling)

Reactor DRUVATHERM® (Laboratory machine)

- DRUVATHERM® reactor at laboratory scale

- Rapid uniting of reacting agents

- Prevention of local overconcentrations

- No temperature gradients within the reaction field

- Improved conversion of reacting agents, leading to higher yield with greater purity of the final product

- Multi-phase proceess (reaction, heating, drying, granulation, cooling)

Ringlayer mixer CoriMix® for continuous operation

- Compact machine unit with high throughput

- Extremely high mixing homogeneity

- Versatile application options

- Easy operation and cleaning

- High operating reliability and service life

The wet mixer

- High mixing quality even for critical products

- Application of high shearing forces

- Easy operation and cleaning

- Reliable and time-tested mixer concept

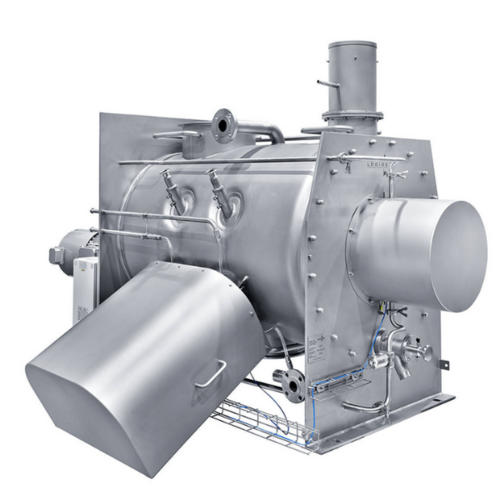

Vacuum shovel dryer DRUVATHERM®

- Intense mixing prevents temperature and moisture gradients within the product

- Maximum heat transfer coefficients ensure excellent dryer performance

- Gentle thermal product treatment in vacuum mode

- Multi-phase process (mixing, granulation, drying, cooling)

- Cost-efficient solvent recovery

Vacuum shovel dryer DRUVATHERM® (Lab machine)

- Reliable scale-up

- Production development under consideration of industrial factors

- “All-in-one process” (mixing, granulation, drying, cooling)

- Intense mixing prevents temperature and moisture gradients within the product

- Short drying times through intense product movement and effective application of thermal energy

- Gentle thermal treatment at low temperatures using a strong vacuum

- Cost-efficient solvent recovery

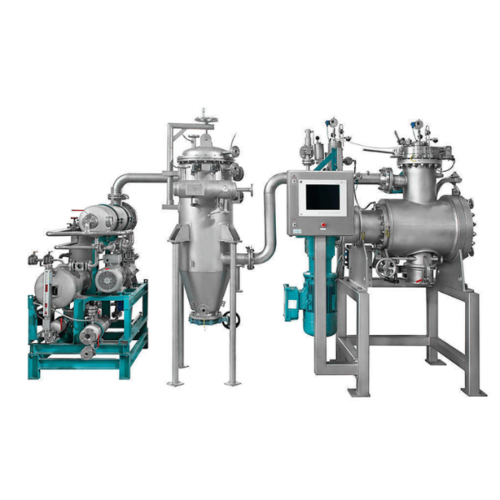

LÖDIGE SYSTEM SOLUTIONS FOR THE CHEMICAL INDUSTRY

Take advantage of our expertise for customised solutions: We manage your entire project efficiently and with minimal interfaces, right through to taking full responsibility for the technical and commercial aspects of the project. So put your trust in our expertise and plan your next project with LÖDIGE!

RESEARCH AND DEVELOPMENT FOR FUTURE-ORIENTED TECHNOLOGIES IN THE LÖDIGE TEST CENTRE

For the development of safe and reproducible production processes, we offer a comprehensive range of testing and analysis facilities in our two modern test centres.

The LÖDIGE Test Centres cover an area of more than 700 m² and have test capacities with more than 30 machines. Mixing, granulation, reaction, drying and coating tests can be carried out, covering the full range of LÖDIGE capabilities.

YOUR CONTACT PERSON

We not only support you in the production of your products, but also see ourselves as a partner in the design of complete systems, from support, planning and production of assemblies to the implementation of turnkey systems.

Get in touch with our experts! Together we can find the perfect solution for your specific needs in the chemical industry.

THE WAY WE WORK:

BEST RESULTS THANKS TO COOPERATION

The high quality of our solutions is based on consistent process design, comprehensive basic engineering and the specific design of the DRUVATHERM® Reactor or Dryer as the central unit of the system.

We are convinced that the best results are achieved through cooperation. That is why we work closely with users in the chemical industry to develop and verify solutions.

WE ARE CERTIFIED & APPROVED

Our commitment to quality is officially confirmed by recognised testing bodies. Find out more here about our industry-specific approvals and certificates.

LET'S HAVE A CHAT

Do you have any questions, suggestions or feedback? Let us know your request using the contact form and we will get back to you as soon as possible: