MACHINES & SYSTEM SOLUTIONS FOR THE ENVIRONMENTAL INDUSTRY

Whether in mining, power stations, steel mills, waste incinerators or wastewater treatment plants, the need for environmentally sound disposal and recycling of residual materials is greater than ever. They affect both the municipal and industrial sectors and require innovative and sustainable solutions.

In this challenging context, LÖDIGE offers process solutions that are specially tailored to the needs of environmental technology. We support our customers with customised solutions having many years of experience in the development and implementation of robust, durable mixing technology for the mechanical, chemical and thermal processing of residual materials.

CHALLENGES IN THE ENVIRONMENTAL INDUSTRY AND OUR RESPONSE

The challenge for the environmental industry is clear: to meet our responsibility to future generations through intelligent technologies and continuous innovation. Our engineering industry must prove itself as a true problem solver and provider of benefits - on a global scale. In a high-tech industrial country, economy and ecology should no longer be contradictory.

In close cooperation with our customers, and on the basis of our expertise in mixing and treatment processes, we implement a project-specific solution for every task. Plant operators and planners in the waste disposal and recycling sector have been relying on our LÖDIGE systems for decades.

FROM WASTE MATERIALS TO BATTERY MASSES:

SPECIAL SOLUTIONS FROM LÖDIGE

Positive environmental technology through LÖDIGE mixing technology means: converting residues from industrial and consumer processes into usable substances. The systems delivered in recent years have proven that our solutions are particularly successful in this respect.

The mixing technology is extremely flexible so that different local requirements can be met. Some examples of applications:

- Sludge conditioning and stabilisation

- Treatment of compost made of a wide range of organic residues

- Treatment of refuse derived fuels

- Immobilisation of waste

- Treatment of incineration residues

- Conditioning of refinery and drilling sludge

- Treatment of metallurgical residues for reuse

- Increasing the adsorption capacity of additives for flue gas desulphurisation

- Preparation of materials for underground use (tailings/backfill)

- Co-use of residual materials for the production of battery masses

LÖDIGE MACHINES

FOR THE ENVIRONMENTAL INDUSTRY

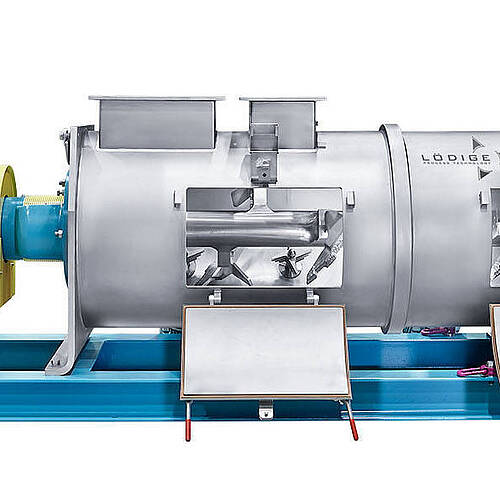

LÖDIGE mixing and reaction systems are versatile: they mix, generate chemical reactions, granulate, neutralise, solidify and produce liquid or pumpable masses. Our mixers, which can be indirectly heated or cooled with a variety of media, can also handle the viscoplastic phase of the products.

Shaft seals and safety devices are available for all systems to ensure safe and efficient processes, even under inert conditions. You will find an overview of our machine range below:

Ploughshare® Mixer (Laboratory machine)

- Guaranteed LÖDIGE quality

- Attractive value for money

- Functional design

- Ideal for your product and process development

- Extensive range of accessories

Ploughshare® Mixers for batch operation "Universal Design"

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

Ploughshare® mixers for continuous operation "Universal Design"

- Excellent homogeneity of the final product

- Retention/mixing times and granulation processes can be adapted to the specific product

- Gentle product treatment

- Consistent reproducibility

- High availability

- Easy accessibility of all internal mixer components

- Low-maintenance mixer concept

Ringlayer mixer CoriMix® for continuous operation

- Compact machine unit with high throughput

- Extremely high mixing homogeneity

- Versatile application options

- Easy operation and cleaning

- High operating reliability and service life

SYSTEM SOLUTIONS FOR THE ENVIRONMENTAL INDUSTRY

We manage your entire project efficiently and with minimal interfaces, right through to taking full responsibility for the technical and commercial aspects of the project. So put your trust in our expertise and plan your next project with LÖDIGE!

PRODUCT DEVELOPMENT UNDER REAL CONDITIONS

Product development is possible under real industrial conditions as the LÖDIGE laboratory machines operate on the same principle as the production machines. A scale-up of the parameters determined in the tests and the knowledge gained about the product behaviour to production scale is possible without restriction.

YOUR CONTACT PERSON

Contact us to find out more about our innovative solutions in the field of environmental technology. Our experts look forward to developing customised solutions to meet your needs and challenges.

THE WAY WE WORK:

INNOVATION & COOPERTION SINCE 1938

We have a strong focus on research and development with our own Test Centre for a wide range of applications. We focus on efficient and sustainable solutions and work closely with our customers from planning and design through to installation and commissioning of the systems.

PLANNING TESTS IN THE TEST CENTRE

This commitment to cooperation and innovation has been with us since the company was founded in 1938 and remains our guiding principle today.

WE ARE CERTIFIED & APPROVED

Our commitment to quality is officially confirmed by recognised testing bodies. Find out more here about our industry-specific approvals and certificates.

LET'S HAVE A CHAT

Do you have any questions, suggestions or feedback? Let us know your request using the contact form and we will get back to you as soon as possible: