ADVANCED SOLUTIONS FOR THE FOOD INDUSTRY

In a world where the quality of our food has a direct impact on our health and well-being, food manufacturers are challenged to produce safe, healthy and tasty products. With an increasing demand for product safety and quality, as well as changing markets and consumer habits, efficient processing methods are becoming increasingly important in this industry.

This is where LÖDIGE gets involved: With our experience in machinery for the food industry, we provide optimised solutions, efficiency, economy and the highest standards of hygienic design. Our mixers and systems for food producers are designed in accordance with EHEDG guidelines and set standards in terms of economy and efficiency all around the world. We help leading companies and well-known brands in the food industry to meet the demands of their markets.

CHALLENGES IN THE FOOD INDUSTRY AND OUR RESPONSE

The food industry in particular requires innovative solutions and advanced technologies not only to ensure food safety and hygiene regulations, but also to optimise product quality and increase the production capacity.

LÖDIGE provides complete solutions and specific systems for the food industry - with a focus on food-safe design. Mixing is the central process step in the production of food, but it is not the only step. Our systems enable the integration of further process steps such as alkalising, greasing, heating, cooling, pasteurising, sterilising and much more. Not only does this save labour-intensive intermediate steps such as premixing, but it also saves significant costs.

FLEXIBILITY OF USE

LÖDIGE machines are reliable components in the production lines of small family businesses and medium-sized companies as well as global players with mass production. Our systems ensure the required mixing and process precision for a wide range of applications. You will find below a selection of food applications produced in LÖDIGE systems:

- Instant soups

- Oven-ready flours / Backing mixes with added fat and lecithin

- Spice mixes / Table salts

- Aromas / Flavourings

- Dry or flavoured instant drinks

- Coffee and tea extracts / Tea blends

- Dietary supplements / Vitamin preparations

- Tobacco

- Sweets / Chocolate

- Muesli / Cereals

- Powdered milk / Whey powder / Baby food

- Enzymes / Starter cultures

- Creams / Dressings / Mustard

- Cheese / Soft cheese

LÖDIGE MACHINES AND MIXERS FOR THE FOOD INDUSTRY

Our machines are easy to handle and to clean as well as flexible in processing a wide range of raw materials - from premixes to finished products. Whether continuous or batch mixers, vertical or horizontal systems, ringlayer mixers or vacuum shovel dryers, LÖDIGE guarantees consistent product quality. You will find below an overview of our machines specifically designed for the food industry.

Mixing granulator (Laboratory machine)

- Laboratory mixing granulator with exchangeable vessel

- Mixing, granulation and temperature control in one machine

- Exchangeable vessels with a volume of 1, 5, 10 or 15 l

- GMP-compliant design

- User-friendly, integrated control system

- Operation-ready system

Ploughshare® Mixer (Laboratory machine)

- Guaranteed LÖDIGE quality

- Attractive value for money

- Functional design

- Ideal for your product and process development

- Extensive range of accessories

Ploughshare® batch mixer type FKM LS

- Newest member of the LÖDIGE program

- Attractive price

- Short delivery time

- “Made in Germany”

- Same manufacturing quality, performance and mixing results as the classic LÖDIGE mixer

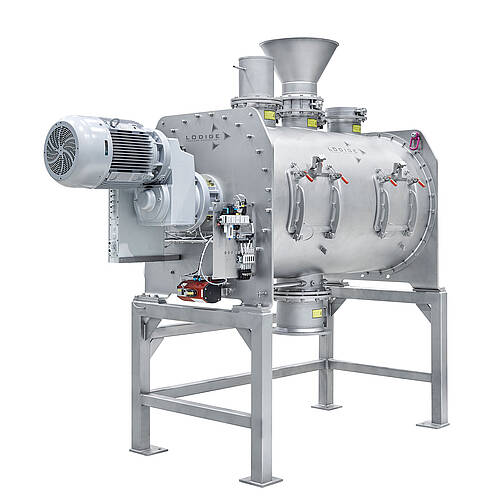

Ploughshare® Mixers for batch operation "Hygienic Design"

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

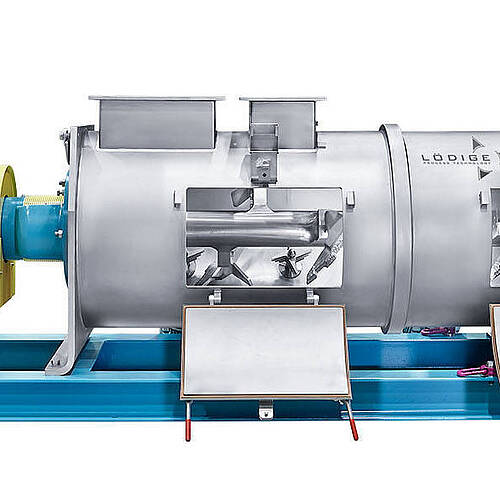

Ploughshare® mixers for continuous operation "Universal Design"

- Excellent homogeneity of the final product

- Retention/mixing times and granulation processes can be adapted to the specific product

- Gentle product treatment

- Consistent reproducibility

- High availability

- Easy accessibility of all internal mixer components

- Low-maintenance mixer concept

Ringlayer mixer CoriMix® for continuous operation

- Compact machine unit with high throughput

- Extremely high mixing homogeneity

- Versatile application options

- Easy operation and cleaning

- High operating reliability and service life

THE LÖDIGE MIXING GRANULATOR

- Mixing granulator for pharmaceutical products, cosmetics and food

- GMP-compliant design

- Modular WIP system for the machine and all additional components

- Automatic liquid addition in different versions

- New pharmaceutical controls

- Temperature control jacket for heating/cooling

- Integrated sieve on machine outlet

- Vacuum feeder

- Customised ATEX concepts

The wet mixer

- High mixing quality even for critical products

- Application of high shearing forces

- Easy operation and cleaning

- Reliable and time-tested mixer concept

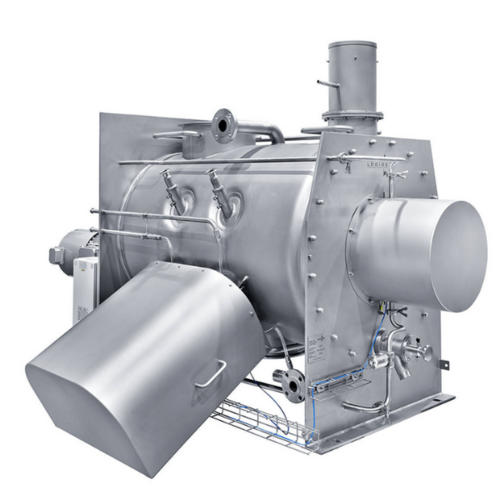

Vacuum shovel dryer DRUVATHERM®

- Intense mixing prevents temperature and moisture gradients within the product

- Maximum heat transfer coefficients ensure excellent dryer performance

- Gentle thermal product treatment in vacuum mode

- Multi-phase process (mixing, granulation, drying, cooling)

- Cost-efficient solvent recovery

Vacuum shovel dryer DRUVATHERM® (Lab machine)

- Reliable scale-up

- Production development under consideration of industrial factors

- “All-in-one process” (mixing, granulation, drying, cooling)

- Intense mixing prevents temperature and moisture gradients within the product

- Short drying times through intense product movement and effective application of thermal energy

- Gentle thermal treatment at low temperatures using a strong vacuum

- Cost-efficient solvent recovery

LÖDIGE TECHNOLOGICAL EXCELLENCE

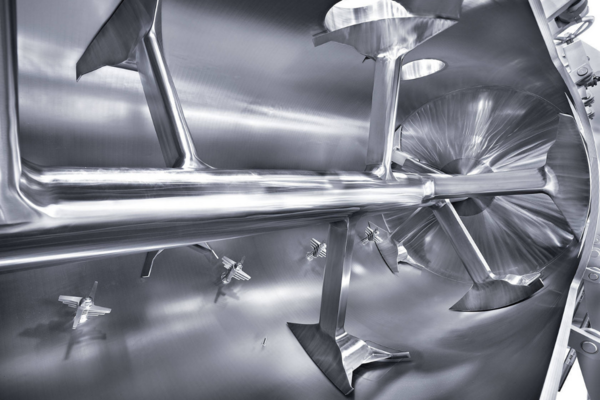

LÖDIGE has a long success story in the food industry. In the 85 years of the company's history, a large number of machines have been supplied for a wide range of applications. These are mainly Ploughshare® Mixers which operate according to the mechanical fluid bed principle first invented by LÖDIGE.

Quality is always our first priority. We take particular pride in manufacturing machines and systems in compliance with the highest standards of hygiene to prevent cross-contamination and to ensure food safety. Our mixers can be equipped with automated washing-in-place (WIP) or cleaning-in-place (CIP) systems.

For special drying applications, our vacuum dryers are specially designed to gently dry temperature-sensitive products, helping to preserve the nutrients and sensory profile of the food.

INNOVATION CENTRE: OUR LÖDIGE TEST CENTRE FOR STATE-OF-THE-ART MACHINE TECHNOLOGY

We have an own Test Centre so that we can constantly work on state-of-the-art, high-quality solutions and perfect our engineering for your food applications.

We have machines at your disposal for test purpose for the following processes: mixing, kneading, dispersing, emulsifying, wet granulation, drying, heating, cooling and coating. There is also a laboratory for physical analysis.

YOUR CONTACT PERSON

Contact us to find out more about how LÖDIGE can help you meet the challenges of the food industry. Our experts look forward to working with you to develop customised solutions to meet your specific needs.

LÖDIGE is your partner for advanced machinery and process technology in the food industry.

THE WAY WE WORK: QUALITY AND EFFICIENCY FROM THE LAB SCALE TO THE PRODUCTION LINE

We understand the importance of flexibility and scalability in food production. Our technology ranges from laboratory scale for research and development to production machines.

By working closely with our customers, we are able to meet the individual needs and optimize to your process in order to achieve the highest levels of quality and efficiency.

DOWNLOADS

WE ARE CERTIFIED & APPROVED

Our commitment to quality is officially confirmed by recognised testing bodies. Find out more here about our industry-specific approvals and certificates.

LET'S HAVE A CHAT

Do you have any questions, suggestions or feedback? Let us know your request using the contact form and we will get back to you as soon as possible: