OPTIMUM SOLUTIONS FOR THE MOST DEMANDING REACTION PROCESSES

Efficient reaction processes in LÖDIGE machines provides an innovative solution for chemical synthesis and process optimisation. Our systems enable you to carry out chemical reactions in a precise and controlled manner. Solid or liquid reactants can be optimally converted into one or more products with new chemical and/or physical properties.

Discover the efficiency and versatility of our reaction processes and optimise your production with LÖDIGE solutions.

APPLICATIONS IN VARIOUS INDUSTRIES

Our reaction processes and reactors are used in a wide range of industries, including the chemical, plastics and polysaccharide industries. Our horizontal reactors are particularly suitable for chemical reactions with solids because they use a mechanically generated fluid bed to ensure excellent mass and heat transfer.

Organic pigments, for example, can be produced directly without passing through a suspension. Polymerisation is particularly well suited to a horizontal mixing reactor because, unlike vertical mixers, it is insensitive to changes in phase state.

THE BEST FOR YOU: A FULL RANGE OF SERVICE

Advice, machines and service - at LÖDIGE you get everything from one source to offer you the greatest possible added value. Customised, project-specific design and precise adaptation to your requirements is our strength. Work with us to fine tune your process.

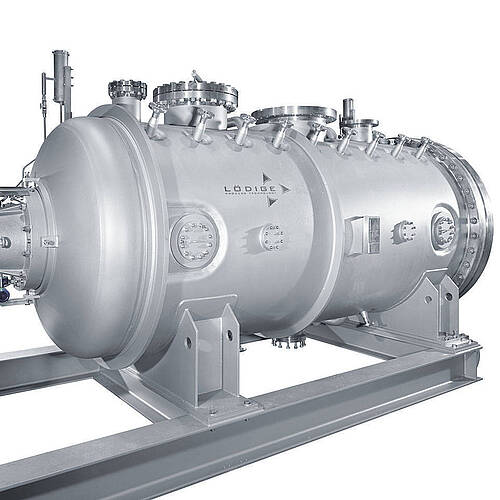

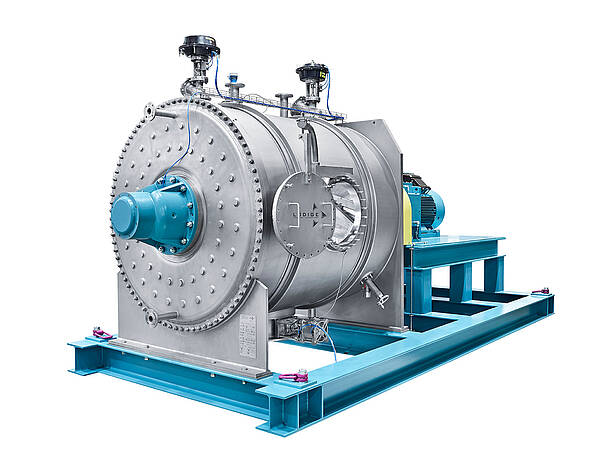

LÖDIGE REACTORS

Our LÖDIGE reactors are designed for efficient use and outstanding performance. They not only provide the fastest mixing of reactants, but also avoid local overconcentrations and are easy to handle.

Our reactors also allow reactions to be carried out without temperature gradients in the reaction zone. This ensures better conversion of the components, resulting in higher yields and the highest purity of the end product. They also support multi-phase processes such as reaction, heating, drying, granulation and cooling.

Reactions in LÖDIGE machines can be performed in both homogeneous and heterogeneous phases and in principle in all combinations - solid, liquid, gaseous.

Reactor DRUVATHERM®

- Rapid uniting of reacting agents

- Prevention of local overconcentrations

- No temperature gradients within the reaction field

- Improved conversion of reactin agents, leading to higher yield with greater purity of the final product

- Multi-phase process (reaction, heating, drying, granulation, cooling)

Reactor DRUVATHERM® (Laboratory machine)

- DRUVATHERM® reactor at laboratory scale

- Rapid uniting of reacting agents

- Prevention of local overconcentrations

- No temperature gradients within the reaction field

- Improved conversion of reacting agents, leading to higher yield with greater purity of the final product

- Multi-phase proceess (reaction, heating, drying, granulation, cooling)

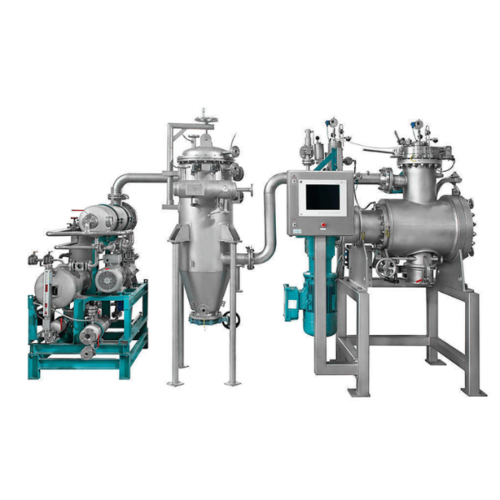

Vacuum shovel dryer DRUVATHERM®

- Intense mixing prevents temperature and moisture gradients within the product

- Maximum heat transfer coefficients ensure excellent dryer performance

- Gentle thermal product treatment in vacuum mode

- Multi-phase process (mixing, granulation, drying, cooling)

- Cost-efficient solvent recovery

Vacuum shovel dryer DRUVATHERM® (Lab machine)

- Reliable scale-up

- Production development under consideration of industrial factors

- “All-in-one process” (mixing, granulation, drying, cooling)

- Intense mixing prevents temperature and moisture gradients within the product

- Short drying times through intense product movement and effective application of thermal energy

- Gentle thermal treatment at low temperatures using a strong vacuum

- Cost-efficient solvent recovery

Can't find a suitable machine?

SINGLE POT PROCESS

The entire process chain in one machine - this is possible with LÖDIGE reactors. Thanks to their versatility, complex process steps such as mixing, liquid addition, heating, evaporation, reaction, drying, cooling, granulation and coating can be carried out in a single machine.

For example, liquid reactants are first mixed and reacted by adding additives. The liquid component is then evaporated to form a solid, which is then dried, cooled and granulated. These steps are carried out without interruption for storage, transport or cleaning.

WE ARE CERTIFIED & APPROVED

Our commitment to quality is officially confirmed by recognised testing bodies. Find out more here about our industry-specific approvals and certificates.

CONTACT US

Reaction systems using LÖDIGE guarantee precisely reproducible, constant and reliable processes. Our DRUVATHERM® reactors have proven particularly successful in the chemical industry, especially in the production of cellulose and starch derivatives, as well as in alkalisation processes.

Contact us today and discover how our advanced technologies can optimise your production processes. Let our experts advise you and learn more about the many applications and benefits of our reaction systems. Together we will find the perfect solution for your specific needs.