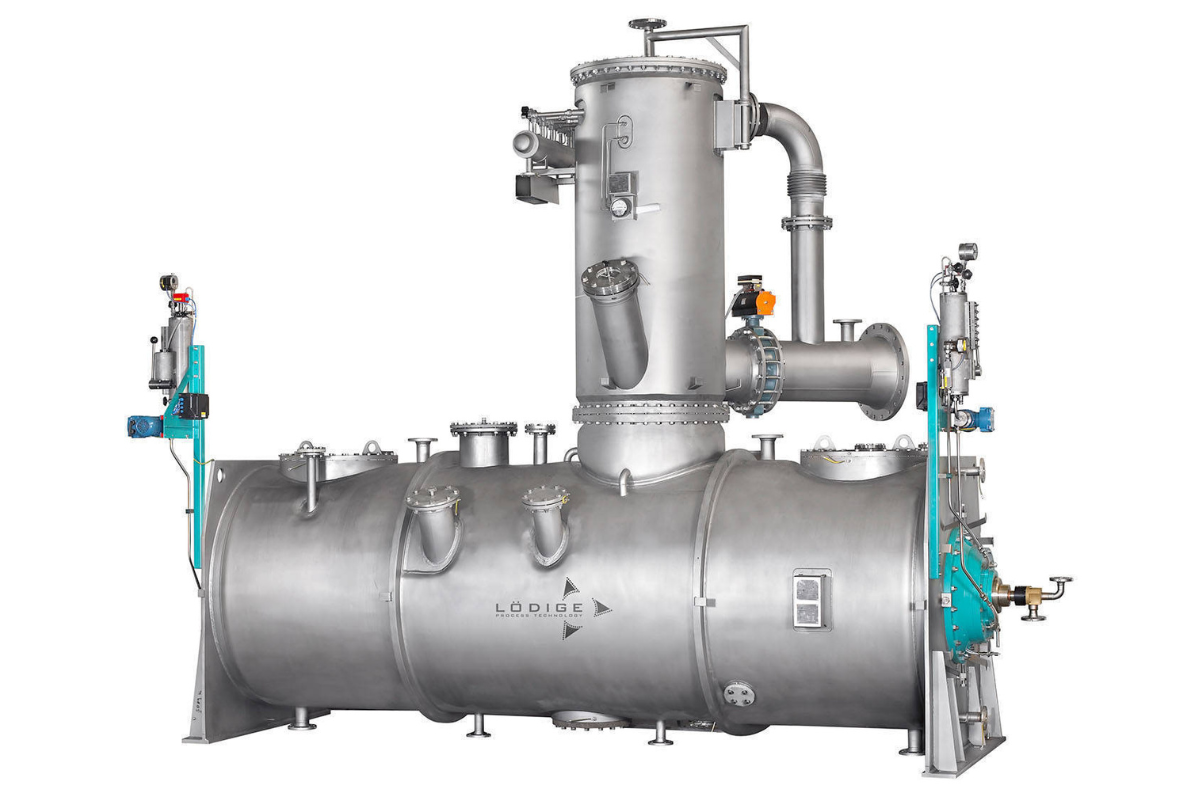

VACUUM DRYER FOR INDUSTRY AND RESEARCH

Vacuum dryers are used in a wide range of industries to dry products in a gentle and efficient manner. Our top-quality vacuum dryers are of high performance and adaptable to your specific requirements. The LÖDIGE DRUVATHERM® Vacuum Shovel Dryers are specially designed to meet the demanding requirements of the pharmaceutical, chemical, plastics and cosmetics industries.

THE PRINCIPLE OF VACUUM DRYING

Vacuum drying is a process in which products are dried under reduced pressure. This minimises the boiling point of the moisture in the product, allowing it to be dried at lower temperatures. This is particularly beneficial for heat-sensitive materials and protects product quality and integrity.

Our DRUVATHERM® Vacuum Shovel Dryers ensure a rapid, uniform and gentle drying of the product. These dryers are ideal for a wide range of applications in various industries as different as the pharmaceutical, chemical, plastics and cosmetics sectors. The main advantages of vacuum drying are the following:

- Low drying temperatures: Ideal for temperature-sensitive products.

- Quick drying: Accelerated evaporation process due to vacuum.

- Reduced oxidation: Product protected by reduced oxygen content.

- Homogeneous drying: Uniform drying results thanks to advanced technology.

- Energy-efficient drying at low temperatures

INNOVATIVE DRYING LÖDIGE SHOVEL DRYER

Drying in batch operation enables high-efficiency and adaptability to different process requirements. The frequency-controlled main shaft with mixing elements generates a product fluid bed which enables precise control and optimisation of each drying process.

UNIQUE MIXING TECHNOLOGY FOR OPTIMUM DRYING

Three-dimensional product movement: The special mixing elements rotating in the cylindrical mixing drum equipped with a heating jacket generates a unique three-dimensional movement of the product. This mechanically generated fluid bed maximises the contact surface between the product and the heating jacket ensuring in this way extremely short drying times.

Intensive heat transfer: The intelligent product movement ensures intensive contact between the product particles and the heated drum wall. This efficient heat transfer not only ensures quick drying, but also gentle treatment of the product being dried. This is particularly important for sensitive materials.

EFFICIENT SEPARATION OF ULTRA-FINE PARTICLES

LÖDIGE Vacuum Shovel Dryers are able to separate efficiently the fine particles accumulated in solvent vapours. A pneumatic filter cleaning mounted on the dryer collects these particles in a reliable manner. This cleaning system returns the particles directly to the product bed, contributing in this way to less product loss and preservation of the product quality.

The combination of advanced drying technology, customised features and efficient particle separation makes LÖDIGE Vacuum Shovel Dryers the ideal choice for industries that value quality, efficiency and process optimisation.

ADDITIONAL FEATURES FOR SPECIAL REQUIREMENTS

For applications requiring additional loosening of the product during a transition phase for example, rotating choppers are available as an option. These choppers are placed at the back of the mixing drum and improve the loosening of the product without affecting the product quality.

LÖDIGE VACUUM SHOVEL DRYER

Discover the advantages of LÖDIGE Vacuum Dryers and set new standards in your production. Our Vacuum Dryers are listed below:

Vacuum shovel dryer DRUVATHERM®

- Intense mixing prevents temperature and moisture gradients within the product

- Maximum heat transfer coefficients ensure excellent dryer performance

- Gentle thermal product treatment in vacuum mode

- Multi-phase process (mixing, granulation, drying, cooling)

- Cost-efficient solvent recovery

Vacuum shovel dryer DRUVATHERM® (Lab machine)

- Reliable scale-up

- Production development under consideration of industrial factors

- “All-in-one process” (mixing, granulation, drying, cooling)

- Intense mixing prevents temperature and moisture gradients within the product

- Short drying times through intense product movement and effective application of thermal energy

- Gentle thermal treatment at low temperatures using a strong vacuum

- Cost-efficient solvent recovery

NO SUITABLE MACHINE FOUND?

WE ARE CERTIFIED & APPROVED

Our commitment to quality is officially confirmed by recognised testing bodies. Find out more here about our industry-specific approvals and certificates.

CONTACT US NOW

LÖDIGE has many years of experience and comprehensive know-how in drying and mixing technology. Our aim is to supply tailor-made solutions to meet the specific requirements of each industrial application. Contact us to find out how our vacuum drying technology can optimise your production process.