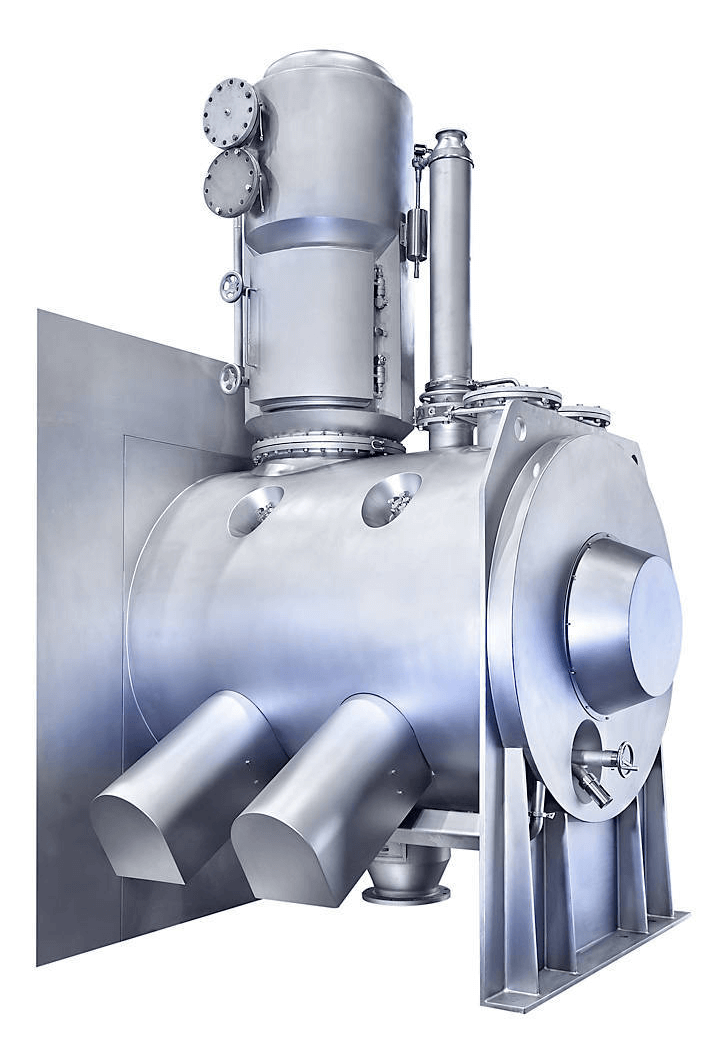

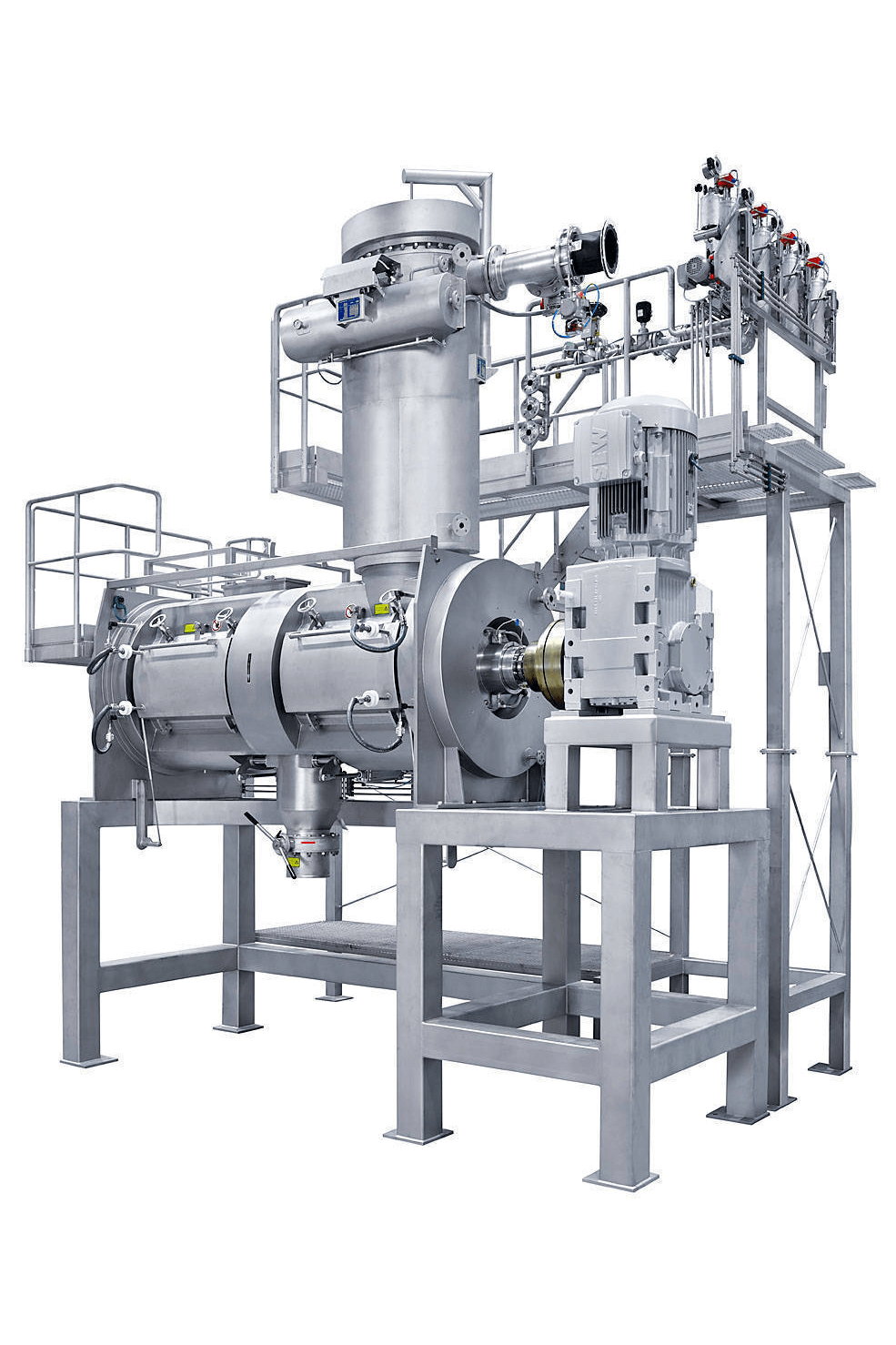

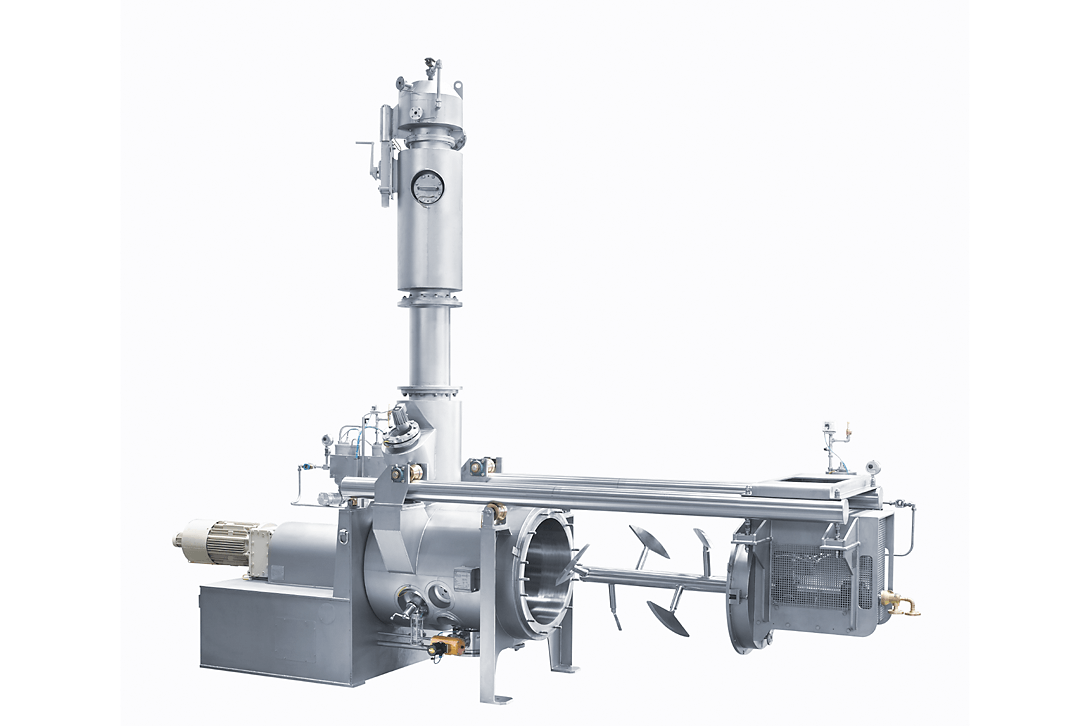

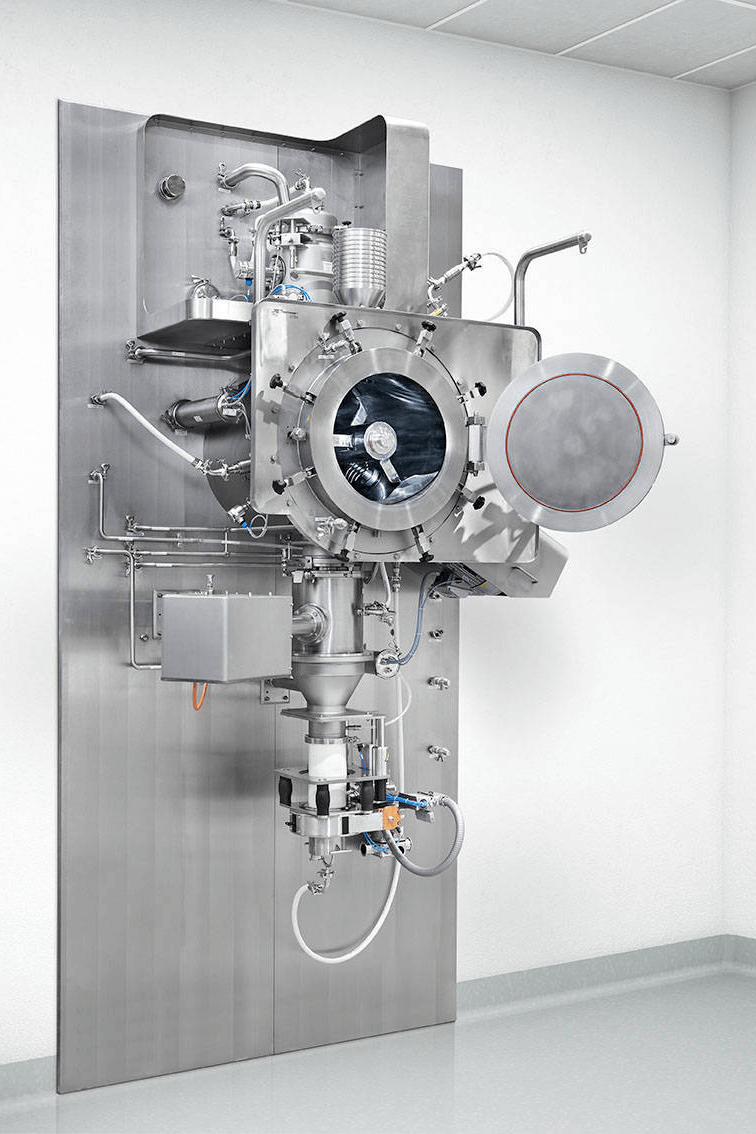

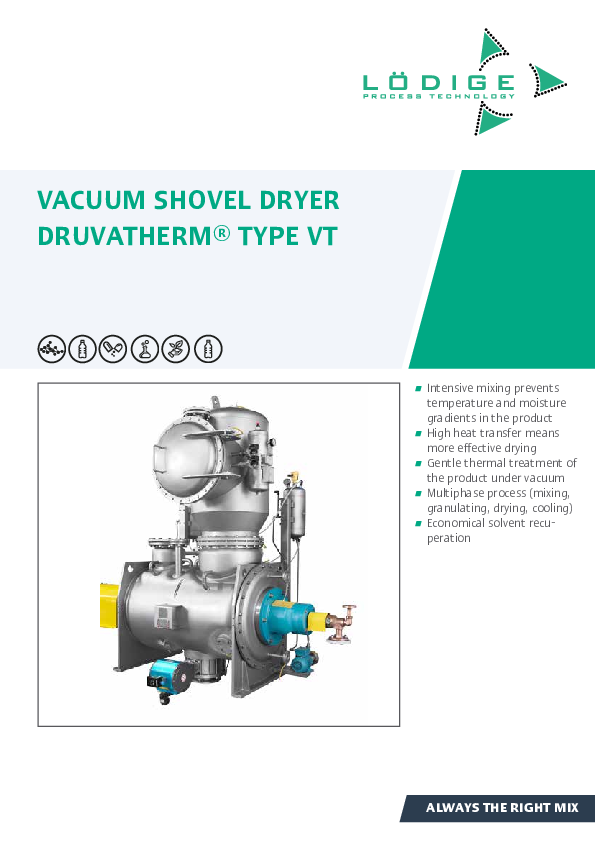

LÖDIGE'S VACUUM SHOVEL DRYER DRUVATHERM®

- Intense mixing prevents temperature and moisture gradients within the product

- Maximum heat transfer coefficients ensure excellent dryer performance

- Gentle thermal product treatment in vacuum mode

- Multi-phase process (mixing, granulation, drying, cooling)

- Cost-efficient solvent recovery

MACHINE TYPE

Lödige shovel dryers are batch vacuum dryers. The mixing elements are frequency-controlled for ideal adaptation to the process. Special rotating mixing elements, installed in a cylindrical drum equipped with a temperature control jacket, create a three-dimensional product movement (mechanically generated fluid bed). The resulting contact frequency of the particles with the heat exchange surface leads to incredibly short drying times.

The intelligent product movement ensures intense contact of individual product particles with the heated container wall while also providing very gentle product treatment. Optionally available rotating choppers, which are installed in the sides of the drum, break down any agglomerated product if a product phase transition is required. Fine particles pulled along by solvent vapours are separated by an installed, pneumatically purged filter and are returned to the drying product bed by the cleaning system.

APPLICATION FIELDS

Trouble finding your industry?

Downloads

WHITEPAPER: ADVANTAGES OF SINGLE-POT SOLUTIONS FOR THE PRODUCTION OF PHARMACEUTICAL GRANULES

WE ARE CERTIFIED & APPROVED

Our commitment to quality is officially confirmed by recognised testing bodies. Find out more here about our industry-specific approvals and certificates.

LET'S HAVE A CHAT

Do you have any questions, suggestions or feedback? Let us know your request using the contact form and we will get back to you as soon as possible: