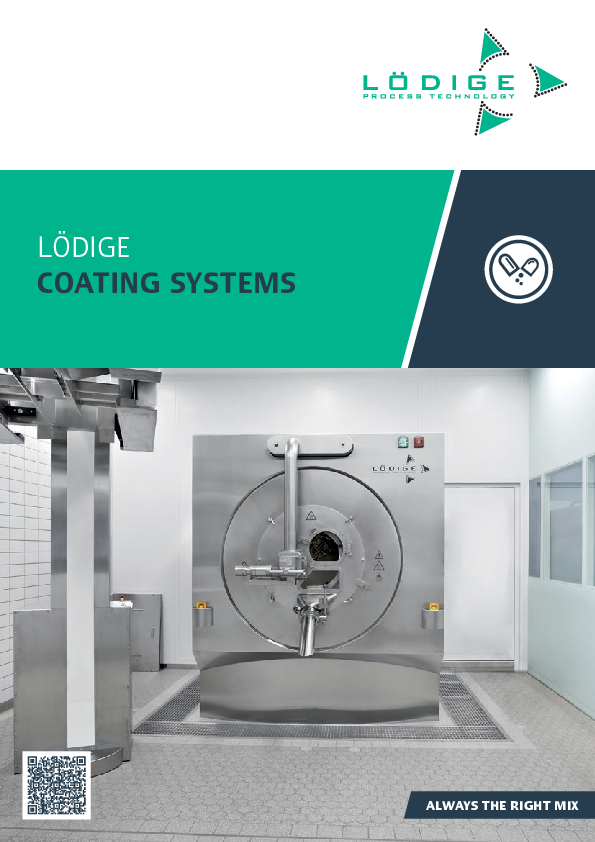

THE LÖDIGE COATER LC: PERFECT RESULTS IN EXTREMLY SHORT TIMES

Filling level variability without drum replacement

- The extremely low height of the mixing elements permits a high degree of filling level variability.

Even application and short process times

- The high number of mixing elements and nozzles ensures ideal distribution and leads to low variance in the evenness of application.

High-speed = Time is money

- The even air distribution throughout the entire drum length ensures that the drying effectiveness is high and permits high spray rates.

Optimised air flow: A quality improvement

- This air flow prevents spray drying, increases service life for campaign production and reduces the cleaning workload.

Simple cleaning

- A sophisticated cleaning system and its great mechanical effect make cleaning quick and efficient. This saves time, cleaning agents and energy.

MACHINE TYPE

The coaters were specifically developed for coating tablets. With our coater range, we are the technological market leader.

The maximised tablet bed surface in the Lödige coater and the maximum number of spray nozzles mean that extremely high liquid volumes can be applied with extremely high air supply volumes within a very short time. The newly designed, particularly low-turbulence air routing ensures a highly efficient and gentle use of dryer air. These features ensure a reliable coating process and short process times. Moreover, the low-turbulence air routing prevents contamination from the very start, thereby reducing the cleaning workload.

Modern sensors permit optimisation of the spraying and drying process.

Simple yet secure nozzle arm adjustment makes for easier handling.

Explosion protection:

- Machine line design for use of organic solvents (acetone, isopropanol, ethanol).

Fully automatic nozzle arm:

- Not only the distance of the nozzle and the tablet bed, but also the spray angle in relation to the tablet bed is controlled.

Sugar coating:

- The Lödige coater can be equipped for production of both film tablets and sugar-coated pills.

Mini tablets or pellets:

- The drum perforation can be adapted to the product using different sizes.

Qualification:

- Complete qualification documentation, incl. risk analysis based design documents, GAMP5 documentation.

Downloads

CONTACT PERSON

Torsten Meinel-Dirumdam

E-Mail: Meinel-Dirumdam(at)loedige.de

WE ARE CERTIFIED & APPROVED

Our commitment to quality is officially confirmed by recognised testing bodies. Find out more here about our industry-specific approvals and certificates.

LET'S HAVE A CHAT

Do you have any questions, suggestions or feedback? Let us know your request using the contact form and we will get back to you as soon as possible: